Manual cleaning

What material do you separate

Construction waste

Wood waste

Wood chips

The above materials are only selected examples, consultation for your specific case is always important.

Contact us

Do you have a question or are you interested in a no-obligation quotation?

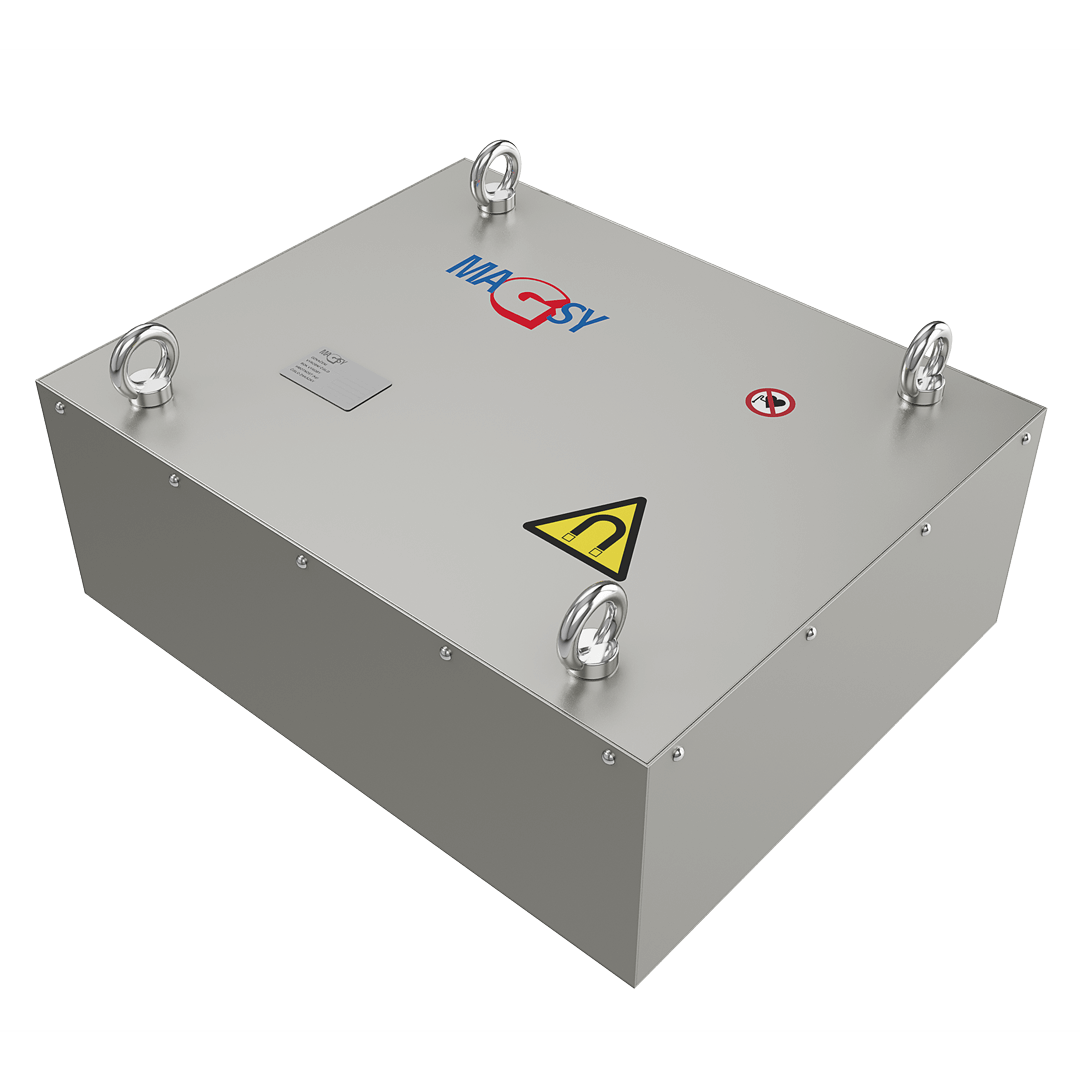

Magnetic plate above belt conveyor

What is the separator suitable for?

-

- Removal of ferromagnetic impurities from materials on conveyors.

- Protecting equipment such as crushers and mills from damage by metal particles.

- Improving the quality of final products in the food, chemical and recycling industries.

Design and cleaning principle of the separator

Important parts of the separator

Magnetic system

Choice of strong neodymium or weaker ferrite magnets depending on application needs.Mounting hinges

Four hanging lugs in the corners for easy installation over the conveyor belt.Durable construction

Adapted for long-term use in harsh conditions.Send us an e-mail

Aveți o întrebare sau sunteți interesat de o ofertă fără caracter obligatoriu?

Why Magsy

Own production hall

23 years on the market

Leading separator manufacturer in Europe

Service team 24 hours a day

Over 50,000+ separators produced

ISO 9001 certificates

How do we pack and ship magnetic separators?

How does the cooperation work?

Product Description

MP magnetic plates are suitable on all places where material preparation using belt conveyors prevails, and the quantity of ferromagnetic impurities does not exceed an acceptable limit for the manual cleaning. In case of materials containing higher metal impurity concentrations, we recommend using magnetic separator placed above a conveyor with an automatic cleaning.

In case of a big separated material thickness, or in case the material permeability is compromised, it is suitable to complete the belt conveyor with the magnetic driving cylinder that will ensure the separation from the lower material layers.

Utilization areas ...