Magnetic rods – main benefits:

- Good magnetic output of separate rods due to strong NdFeB magnets

- Minimum magnetic output losses due to a thin, worked pipe wall.

- The product has flexible dimensions. MAGSY manufactures magnetic rods according to dimensions given by customers.

Non-comfortable system of magnetic rods cleaning from Fe impurities is a disadvantage. The cores cannot be pulled out.Pipe wall is machined to as low as possible thickness, in order to minimize the magnetic force losses. Magnetic core consists of cylindrical NdFeB magnets and pole extensions.

Standard magnetic parameters of MAGSY rods are on the three levels.

As a standard, MAGSY manufactures MR magnetic rods in two diameters and several lengths.

- MR with the diameter of 25 mm: the lengths are 150; 200; 250; 300; 350; 450 and 500 mm

- MR with the diameter of 30 mm: the length is 250 mm.

Magnetic rod cleaning is always manual. Wipe Fe impurities off from the rod surface by hand.

Customers prefer magnetic rods mainly in certain grate dimensions. Own grate is made by customers by themselves.

Magnetic rods are made-on-measure by MAGSY in various lengths and flexibly, based on a submission.

Magnetic rods – industrial utilization areas

1. Use in dry materials

In fact, MR magnetic rods, as parts of magnetic grates, may be used in all industrial areas where the medium to be cleaned is represented by a dry, homogeneous material, or dry material mixtures in very small or fine fractions. Good loose parameters need to be provided at all times.

Grates made of magnetic rods are not suitable for using with abrasive media because the pipe wall is machined to a very small thickness so the tear and wear of the pipe may come very quickly. This deals also with materials with adhesive behavior. Rod-made grates are usually stationary, i.e. the grates may become clogged due to the material “arching”.

Utilization areas:

- Agricultural product industry, feeding mixtures, especially food industry

- Building matter industry, ceramics and porcelain industry, chemical industry

- Polymer and rubber processing industry and other industrial areas where dry, loose bulk material is processed.

WARNING

Due to the facts that separate rods are supplied per order and the customer creates his magnetic grate by himself, the question of so called “fall labyrinth” is not solved on the MAGSY side. This indispensable condition of a proper separation efficiency is solved and covered by the MAGSY company only in cases of separators belonging completely to the company portfolio (MST, etc.).

MR magnetic rods – general technical specification

Magnetic equipment

- Very strong NdFeB magnets

- Magnetic cylinder, outer diameter Ø= 24 mm or 29 mm

- Rod, outer diameter Ø= 25 mm or 30 mm

- Magnetic material temperature resistance: 80˚C as a standard

- Optionally: up to 120˚C (or, possibly, even higher temperatures)

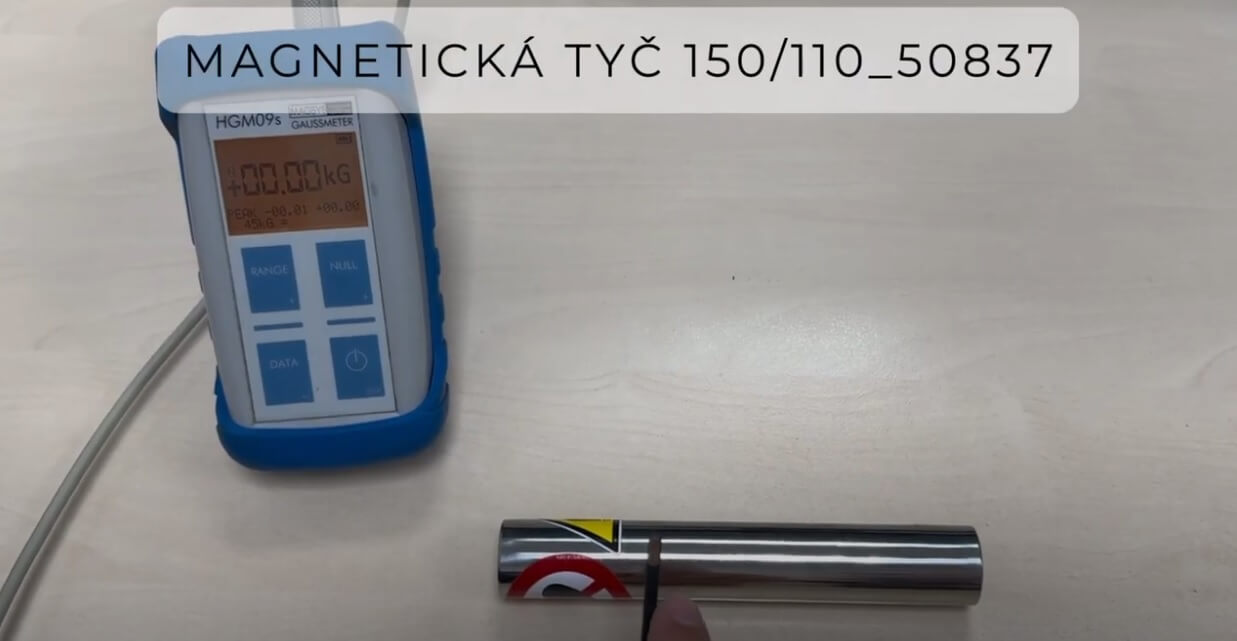

Magnetic induction

The system

- magnetic core is closed in a rod, the core cannot be pulled out

Rod design

- the rod is closed, the wall pipe is machined to the thickness of 0.6 mm at max

Rod material

- as a standard, this is stainless steel 1.4301 / AISI 304.

- optionally: 1.4404 / AISI 316

- all materials are performed in a quality according to EU norms with respective certifications

Surface treatments

- outer rod surface is treated by polishing

Connecting elements

- inner screw M12 is on one of the rod sides – on the forefront

Engineering design

All engineering workmanship and machining operations are performed in own production facility, using own MAGSY engineering technology and own machines. MAGSY CZ machine park is modern.

Component welds

Component welds are performed according to requirements of technological norms dealing with stainless material welding. Due to very strict outgoing control, top quality of joints is guaranteed.

Magnetic testing rod

The test is performed in a manner that the rod is immersed into the inspected material (as you choose, the material may be either dry or liquid), and, with rotational movement, it is tested whether the material contains magnetic impurities that are caught in the lower – functional rod half.

Magnetic rods – main benefits:

- Sufficient magnetic output for magnetic impurity testing

- They are possible to be used with all materials, both dry mixtures and liquid matter

Magnetic core of the magnetic testing rod is equipped with strong NdFeB neodymium magnets. Inside of the pipe, the magnetic core is movable, from the lower half to the upper one and back. To make the core movement, pull bar ended with a handrail is used. In case the magnetic core is situated in the lower rod half, the rod becomes magnetically active and impurities are caught on the rod surface, in its lower, functional half.In case the magnetic core is pulled up to the upper rod half, the lower rod half is without the magnetic action. Magnetic impurities that were caught on the rod previously, fall out spontaneously. Separation collar located in the rod half serves to prevent getting of magnetic impurities from the lower to the upper half.

Therefore, testing rod cleaning principle is that you pull the plastic handrail and the magnetic impurities fall out of the rod surface in the lower half.

As a standard, MAGSY offers two testing magnetic rod types.

In both types, the functional magnetic length is 140 mm.

- MTR Ø 20 mm; magnetic induction is ca 5500 G.

- MTR Ø 30 mm, magnetic induction is ca 6500 G

(magnetic parameters = as measured on the magnetic core surface)

MTT magnetic testing rods – general technical specification

Magnetic equipment

- Very strong NdFeB magnets,

- Ring magnet outer Ø= 19 mm or 29 mm,

- Rod outer Ø= 20 mm or 30 mm

- Magnetic material temperature resistance: up to 80 ˚C as a standard

Magnetic output

- Rod Ø 20 mm = 5500 G, Rod Ø 30 mm = 6500 G. Measured on the magnetic core surface.

The system

- Magnetic core closed in the rod. The core is movable, upwards and downwards.

Rod design

- Closed rod, pipe wall is machined to the thickness of 0.6 mm at max.

Rod material

- As a standard, stainless steel 1.4301 / AISI 304

Handrail material

Surface treatment

- Outer rod surface is treated with polishing.

Engineering workmanship

All engineering workmanship and machining operations are performed in our production plant, using own MAGSY engineering technology and own machines belonging to a modern MAGSY CZ machine park.