Manual cleaning

What material do you separate

Poppy seeds

Grain

Sand

Plastic granulate

Sunflower seeds

Gum

Rubber recyclate

Spices

The above materials are only selected examples, consultation for your specific case is always important.

Contact us

Do you have a question or are you interested in a no-obligation quotation?

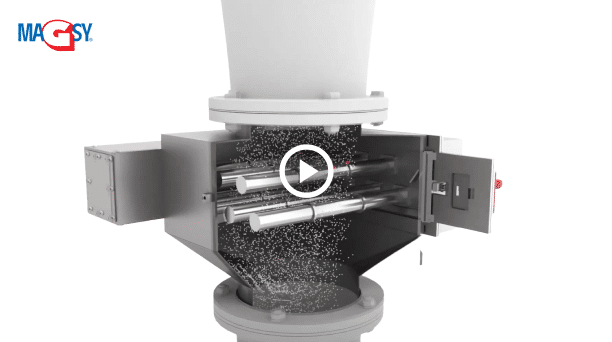

Magnetic separator with telescopic grates

What is the separator suitable for?

-

- For bulk mixtures with manual cleaning of the separator

- Separates the finest impurities from 1.0 µm

- High magnetic performance up to 17,000 G of magnetic induction at the core

- Not suitable for abrasive substances

Design and cleaning principle of the separator

Important parts of the separator

Pull-out magnetic grids

Magnetic grates are easily extendable, providing easy access for cleaning and maintenance of the separator. This design increases operational efficiency and reduces service time.Strong neodymium magnets

The separator is equipped with high-performance neodymium magnets, which enable effective capture of even very fine ferromagnetic particles from the material stream.

Robust stainless steel construction

Durable stainless steel construction ensures a long service life and reliable operation even under harsh industrial conditions.Send us an e-mail

Aveți o întrebare sau sunteți interesat de o ofertă fără caracter obligatoriu?

Model series

Why Magsy

Own production hall

23 years on the market

Leading separator manufacturer in Europe

Service team 24 hours a day

Over 50,000+ separators produced

ISO 9001 certificates

How do we pack and ship magnetic separators?

How does the cooperation work?

Product Description

MST-UP is manufactured either for connections to circular pipes, or for connections to square pipes.

MSV-UP standard models and sizes:- For the circular pipelines with the diameters: 200; 300; 400 mm

- For the square pipelines with the diameters: 200×200; 300×300; 400×400 mm

MSV – UP separator main benefits: ...If needed (untypical mating dimensions, insufficient construction height), MAGSY is ready to produce the MSV-UP separator with modified dimensions, according to your instructions, per your order.

Size models and the separator design

MST-UP is manufactured either for connections to circular pipes, or for connections to square pipes.

MSV-UP standard models and sizes:

- For the circular pipelines with the diameters: 200; 300; 400 mm

- For the square pipelines with the diameters: 200×200; 300×300; 400×400 mm

If needed (untypical mating dimensions, insufficient construction height), MAGSY is ready to produce the MSV-UP separator with modified dimensions, according to your instructions, per your order.

MSV – UP separator main benefits:

- Reliable separation – the labyrinth with at least two grate stages.

- High separation quality – the strongest NdFeB magnets are used, and the magnetic force loss is reduced by an accurate core covering pipe machining to the thickness of 0.6 mm at max.

- Adjustable level of the core magnetic equipment, on the levels I, – VI. – this means the right separation task solving as a function of operational conditions.

- Innovative solution of the whole system including outstanding core covering design and a possibility of an easy replacement of separate covering pipes. This means saving of operational costs regarding the device maintenance.

- The device is compact, the grates are parts of the case, Fe waste receptacle is removable and is the product part – it does not require any additional cleaning aid.

- The most user-friendly cleaning system = by pulling the separate component out, operator working time is reduced. There is a high working safety protection level!

- The highest engineering workmanship level – the best materials used, high engineering workmanship precision, resistance, durability, readiness to assembling operations.

MSV-UP is a compact device where the grates and magnetic cores form an independent component that is traveling (or moving out of the case) from the separator to one side. The component travel is guided on precise linear lines. The system ensures a possibility of entirely comfortable and very sure grate Fe-impurity cleaning system, especially from the working safety point of view. Within the separator cleaning process, operator hands do not get into a contact with the magnetic cores at all, so the risk of injury is minimum here! The removable Fe-waste receptacle is a part of the separator. The separator does not require any additional cleaning preparation.

In the slide-out position, magnetic cores are covered with a flexible sac. This way the cores are protected against outer environment effects and damaging. Core covering pipes are removable individually. This means a significant reduction of the device maintenance costs given by the covering pipe wear and tear.

Tear-resistant covering pipes – RPFA special surface treatment

For using with very abrasive materials, we supply the covering pipes treated with a top-quality surface treatment. This special surface treatment has the thickness of 200 μm, and it is capable of reliable, long-term pipe protection against wearing out.

MSV UP cleaning steps

MSV-UP general technical specification

Magnetic equipment

- Very strong NdFeB magnets situated in the covering pipes

- Inter-circular magnet has the outer Ø= 29 mm; the pipe outer Ø= 31-32 mm, according to the magnetic output

Magnetic material temperature resistance

- As a standard: up to 80 ˚C

- As an option: up to 150 ˚C

Magnetic output

Grate system

- An independent, sliding-out component with movable grates and cores

Dropping labyrinth

- Magnetic grates on two levels at least

Linear guiding of the travel

- Very precise linear guidance, dust-tight sealed sliding surfaces

Case and grate material

- As a standard: stainless steel 1.4301 / AISI 304

- As an option: stainless steel 1.4404 / AISI 316L (for acidic pH values)

Case sealing material

- As a standard: rubber sealing related to the quality corresponding to the separation task and operational conditions

- As an option: food industry sealing conforming to food industry requirements

Flexible sac material

- Kortexin

Surface treatment

- Case outer surfaces and grate frame: machine blasting using a ceramics mixture

- Grate pipe outer surface: machine blasting, polishing as an option, anti-abrasive

- Case inner surfaces are machine blasted. To meet food industry requirements, the corners and welds inside of the case are machined according to the food industry standards (as an option)

Mating dimensions

- Using a flange as a standard, according to respective pipeline dimensions

- Or optionally: JACOB clip, according to respective pipeline dimensions

Counter-flanges are parts of the product. Other connecting elements (e.g. „smooth pipe“) are, as non-standard versions, possible as an option.

Engineering workmanship

All engineering workmanship operations are carried out on machines belonging to the company production facility, using own MAGSY CZ engineering technologies.

Component welds

They are performed according to requirements of valid technological norms dealing with stainless steel material welding. Demanding outgoing weld quality control guarantees a high outgoing production quality.

Ask us – we will advise you!

Made-to-measure production is our strength.

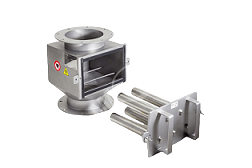

Magnetic separator with telescopic grates MSV

Through the separator, the medium separated flows gravitationally, i.e. the MST separator is designed for vertical pipelines. A moderate pipeline slope of ca 15˚ from the vertical axis at maximum is admissible only in materials with best loose parameters. Note: these MST we supply also for the pneumatic transportation, e.g. behind a plastics material vacuum pump.

MST industrial areas of utilization

In practice, MST magnetic separator is suitable for using in all industrial areas where a dry, homogeneous material or dry material mixture is separated in fine or very fine fractions; however, good loose (bulk) parameters must be observed.

Utilization areas:

- Agricultural product industry, feeding industry, and especially food industry

- Building matter production, ceramics, porcelain and chemical industries

- Rubber and plastics processing industry, recycling and waste processing industry

- Also other industrial areas where dry materials with good loose parameters are processed

MST grate-type separator is not suitable in abrasive matters (the pipe wall is machined to a small thickness of ca 0.6 mm), and also for materials with an increased adhesion (the grates are stationary – there is a risk of the separator clogging due to so called “arching” of the material).

Utilization area in the industrial sphere:

-

Separation for the technology protection in operations:

Technology protection separation is aimed at ferromagnetic impurity removal from a medium, purposed at the technological device protection (cutting knives, mills, etc.) against their damaging. The separator is positioned already during the medium processing, namely before the technological units that need to be protected against damaging by Fe particles. Grate magnetic cores are, from their power point of view, equipped with strong NdFeB magnets. Their composition or the core assembly is aimed at catching of medium size, fine to small impurities (up to the size of 1.0 mm) that could damage subsequent technological devices. In practice it means that core compositions on the levels I or II are used.

-

Separation focused on the product cleanliness:

The separation is aimed at cleaning of the own product from ferromagnetic impurities for the purpose of as good as possible product cleanliness. In this case, the separator is situated especially on the production process end, or within its core, on more places. This is the most efficient method. From the power viewpoint, grate magnetic cores are equipped with the strongest NdFeB magnets, and the magnetic core composition is assembled to catch fine to the finest impurities (since 1.0 µm). Practically it means that core compositions on the levels III – VI are used.

MSV telescopic separator – the design and functioning

Main components of this magnetic separator are represented by telescopic magnetic grates located in the house with a case design. Separator case is installed into the material pipe system, at best in the vertical position, in the loose medium free fall direction.

Magnetic grates form a magnetic field in which magnetic particles, impurities are induced and attached to the pipe surface where there remain caught, mostly in the lower pipe part.

Telescopic magnetic separator located in a case structure

FE impurities are caught on the lower pipe side

Functioning of all grate-type separators is based on a strong magnetic induction and the tear-off force on own grate pipe surface, not on a deep magnetic field. Because of that, any impurity must be led to a contact with the magnetic pipe, or to its immediate proximity.

Case type magnetic grates must be therefore located one above another, in order to provide that separate pipes of both grates mutually form an efficient dropping labyrinth.

Therefore, a proper pipe labyrinth is – besides the magnetic force – an essential condition of proper functioning and efficiency of any grate-type separator.

MAGSY disposes of knowledge and long-term experience in assembling of grate labyrinths, in dependence on separated medium and its parameters.

Magnetic grates in the MSV separators

Magnetic grates are sliding independently from the MST separator case. According to the separator size, magnetic grates contain a defined number of magnetic pipes in order to provide that the dropping gap between the pipes in both the horizontal and vertical directions respects proper labyrinth requirement, when respecting medium flow.

In the grate pipes, magnetic cores are situated that are formed by circular magnets and pole distances. Also, the magnetic cores slide from the grate pipe.

By pulling the cores from the grate pipes the grates becomes de-magnetized that is an essential assumption of an easy grate cleaning.

All MST separators require regular manual grate cleaning from magnetic impurities. Cleaning frequency cannot be stipulated generally. It always depends on the size of Fe impurity portion in own medium.

It always depends on the size of Fe impurity portion in own medium. Grate cleaning interval must be adjusted to the value because any excessive deposit of impurities on the grate pipes reduces the separation efficiency significantly.

Because of that it is necessary to only use the MST separator in discontinuous operations where it is possible to keep regular, sufficiently frequent manual grate pipe cleaning operation.

MSV dropping labyrinth

Efficient functioning of all grate-type separators is based on

- A sufficient magnetic induction (Gs) on the grate surface and near the pipes

- On a high tear-off force (N) on the own grate pipe surface

- And on a proper, efficient dropping labyrinth of the grate pipe within a medium flow

Hence, the magnetic field depth is not crucial. Because of that, any impurity must be led to a contact with the magnetic pipe, or to its immediate proximity.

Magnetic grates in cases must be therefore situated on at least two stages above each other, in order to provide that separate pipes of both grates mutually form an efficient dropping labyrinth.

A labyrinth formed by a grate with only one stage of magnetic pipes is, from the separation efficiency point of view, insufficient. In urgent situations (e.g. insufficient construction height), the single-stage grate may be used but a solution like this cannot provide a sufficient separation quality. In any case, it is advisable to replenish the single-stage separator with drawing-apart roofs at least.

The method of separation using grate-type separators with stationary grates is very efficient also in materials with good loose parameters but no – even the strongest possible – magnetic induction is capable of compensation of a good labyrinth function in the system of separation using grate separators.

A suitable labyrinth created by at least two magnetic grates located above each other is, therefore (besides the magnetic force) the main and essential condition of a proper functioning and effectiveness of any grate-type separator!

Type designation and the product series

MAGSY manufactures the MST separators in the three product groups: Classic, UP, EKO. Each of the groups includes several models, according to the magnetic separator size. Individual MST product groups distinguish according to customer needs. This means by their design, workmanship and different preferences as for the magnetic force level, comfort level in the cleaning system, and on the level of operator working safety provision as well.

Ask us – we will advise you!

Made-to-measure production is our strength.

Magnetic separator with telescopic grates MSV – Classic

MST-Classic – standardly manufactured models and sizes:

- For a round pipeline with the diameters: 100; 150; 200; 300; 400 mm

- For a square pipeline with the dimensions: 100×100; 150×150; 200×200; 300×300; 400×400 mm

If needed (untypical mating dimensions, insufficient construction height), MAGSY is ready to produce the MSV Classic in modified dimensions, according to instructions, per your order.

MSV – Classic main benefits:

- Reliable separation – a labyrinth with two grate stages.

- High separation quality – the strongest NdFeB magnets are used, and the magnetic force loss is reduced by an exact machining of the core covering pipe to the thickness of 0.6 mm at max.

- Adjustable quality of the core magnetic equipment, on the levels I, – VI. –

- a proper separation task solution as a function on operational conditions and the separation task.

- High level of the engineering workmanship – only best materials are used, very high engineering precision, resistance, durability, assembly readiness.

- User-friendly cleaning system – the system of telescopic grates and cores, reduction of the working time losses and the number of operators needed.

Based on the magnetic separation task, i.e. either the technology protection or the medium product protection, and also according to the task operational conditions, the separator may be equipped (from a viewpoint of its magnetic output) by various magnetic core compositions, namely on all four standardized levels. This means that either the magnetic induction value is prioritized, or the tear-off force value needs to be preferred. According to these criteria, core compositions on the levels I. to VI. is selected.

MST-Classic grates and magnetic cores are independently telescopic. This system ensures the possibility of comfortable and good grate cleaning from Fe impurities. From the working safety point of view, during the grate cleaning, however, one must be very careful on pulled-out grates and cores handling because careless manipulation = danger of injury of hand fingers.

Note

For a further facilitating the magnetic grate cleaning process and, especially, to improve the working safety during MST-Classic grate cleaning, MAGSY manufactures special cleaning preparations..

MST-Classic general technical specification

Magnetic equipment

- Very strong NdFeB magnets located in covering pipes.

- Circular magnet with the outer Ø= 29 mm, a pipe with the outer Ø= 31-32 mm according to the magnetic output.

Magnetic material temperature resistance

- As a standard: up to 80 ˚C

- As an option : up to 150 ˚C

Magnetic output (power)

- by a selection from the 4 levels, I – VI, according to the separation task and operational conditions

Grate system

- stationary, telescopic grates and telescopic magnetic cores

Dropping labyrinth

- magnetic grates on at least two stages

Case and grate material

- As a standard: stainless steel 1.4301 / AISI 304.

- As an option: stainless steel 1.4404 / AISI 316L (for acidic pH values)

Door material

- As a standard: stainless steel sheet metal, the quality corresponds to the case

- As an option: PMMA plexi-glass (poly-methyl-methacrylate)

Door sealing material

- As a standard: rubber sealing in the quality corresponding to the separation task and operational conditions

- As an option: food industry sealing in a conformity in compliance with the food industry

All materials are quality-certified according to EU norms.

Surface treatment

- Outer case surface and grate frame: machine blasting by ceramics mixture

- Outer grate pipe surface: machine blasting or polishing as an option

- Case inner surfaces are blasted by machine. In case the application is considered in the food industry, the corners and welds inside of the case are machined according to food industry standards (as an option).

Connecting elements

- Using a flange as a standard, according to the appropriate pipeline dimension

- Or optionally, using JACOB clips, according to an appropriate pipeline dimension

Counter-flanges are parts of the scope of supply. Other connecting elements (e. g. „smooth pipe“) are available as an option as they do not belong to standard accessories.

Engineering operations

All engineering operations are made using the machines of MAGSY CZ own production, utilizing own engineering technologies.

Component welds

They are made according to requirements of valid technological norms respective to the stainless steel material area. Due to a strict outgoing weld inspection, high output product quality is guaranteed.

MSV cleaning preparations

Regarding their separators, MAGSY, as the separator manufacturer, is strongly focused on the facilitating of the cleaning techniques and improving of the cleaning comfort. To simplify the own process of manual separator cleaning, MAGSY manufactures the cleaning preparations that are offered as additional, optional separator equipment.

MST-Classic cleaning preparation serves to simplify the cleaning process as such, increase the cleaning comfort and improve the working safety on magnetic grate handling. The material is: stainless steel sheet metal 1.4301

Cleaning preparation working instructions:

- Fasten the grate with cores into the holder situated on the cleaning preparation (No.1)

- After the clip (No.2) has been released, the cores are pulled out of the grate (No.3)

- Separated cores pulled out of the grate are stored into a self-contained compartment (No.4) where they are covered against own damaging and pollution and, at the same time, they are ensured from an injury point of view.

- An independent, empty grate is then without the magnetic field. Fe impurities fall away from it freely to the waste compartment. Residual impurities may be wiped-off by a brush quite easily.

Cleaning preparation using:

- Cleaning comfort increase

- Working safety improvement

- Magnetic core resistance increase

MAGSY recommends using the cleaning preparations to clean separators.

Magnetic separator with telescopic grates MSV – EKO

Separator size models and design:

MST-EKO is manufactured for connections within round or square pipelines.

As a standard, MSV – EKO is manufactured only in the models with the following dimensions:

- For the round pipelines with the diameters: from 100 mm to 200 mm

MST-EKO is manufactured only on one magnetic equipment level, namely with the magnetic output: magnetic inductions 8900 +/- 500 G and 108 +/-10 N, as measured on the magnetic rod surface.

MSV – EKO separator main benefits:

- Reliable separation – two-level grate labyrinth

- High separation quality – using of the strongest NdFeB magnets, and lowering of the magnetic force loss is achieved by a precise core covering rod machining, to the thickness of 0.6 mm at maximum.

- High engineering processing level – the best materials are used, there is a high precision of the engineering workmanship, resistance, durability and assembling readiness

- Low-cost price category with regard to the simple design.

A disadvantage consist in the non-comfort method of the separator magnetic rod cleaning from Fe impurities.

MST-EKO separation component is formed by closed magnetic rods that are attached to front, load-bearing separator case wall. As a t, separator grate slides from the case but the cores cannot be moved out independently.

Magnetic grate cleaning can be done only manually, by gradual cleaning (retracting) of Fe impurities from the magnetic rod surface, overcoming the magnetic force resistance.

This is a less comfortable cleaning technique compared to MST-Classic or, especially, to the system used by MST-UP. During the grate cleaning, extraordinary attention must be paid also to the working safety. Careless manipulation means a danger of hand finger injury.

MSV-EKO general technical specification

Magnetic equipment

- Very strong NdFeB magnets, placed in closed magnetic rods.

- Magnet cylinder Ø= 29 mm, outer rod Ø= 31 mm

- Magnetic material temperature resistance: as a standard, up to 80 ˚C only

Magnetic output

- The only level is 8900 +/-500 G // 108 +/-10 N, as measured on the rod surface

Grate system

- Stationary pulling-out grate, fixed magnetic cores

Dropping labyrinth

- magnetic grate on two levels

Case and grate material

- As a standard, stainless steel 1.4301 / AISI 304 only

Door material

- As a standard, stainless steel sheet metal only, in the quality given by the case

Case sealing material

- As a standard: rubber sealing in the quality given by the separation task and operational conditions

- As an option: food industry sealing in compliance with food industry standards

All materials are quality-certified according to EU norms.

Surface treatment

- Outer case surfaces: machine blasting using a ceramics mixture

- Outer rod surface: without any treatment, or polished as an option.

- Inner case surfaces are machine blasted. For the food industry purposes, corners and welds inside of the case are machined according to food industry standards (as an option).

Connection elements

- Only with a flange as a standard. Counter-flanges are parts of the product.

Engineering workmanship

All engineering workmanship operations are carried out on machines belonging to the company production facility, using own MAGSY CZ engineering technologies.

Component welds

They are performed according to requirements of valid technological norms dealing with stainless steel material welding. Demanding outgoing weld quality control guarantees a high outgoing production quality.

Ask us – we will advise you!

Made-to-measure production is our strength.