Automatic cleaning

What material do you separate

Plastic grit

Beet pulp

Construction waste

Wood waste

Rubber recyclate

The above materials are only selected examples, consultation for your specific case is always important.

Contact us

Do you have a question or are you interested in a no-obligation quotation?

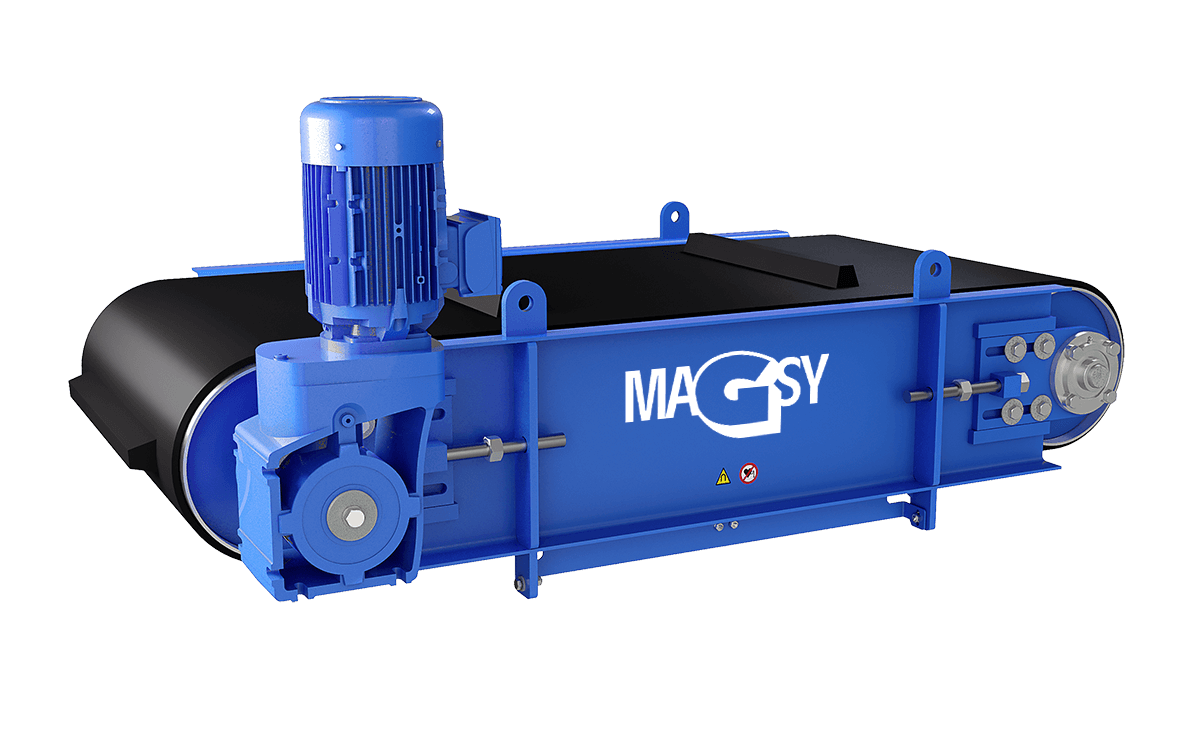

Magnetic separator over conveyor

What is the separator suitable for?

-

- Easy installation above the conveyor, with four hanging lugs

- Separator width up to 1600 mm, magnet thickness up to 300 mm

- Maximum belt speed must not exceed 1.5 m/s

- Suitable for waste sorting, recycling, well permeable material

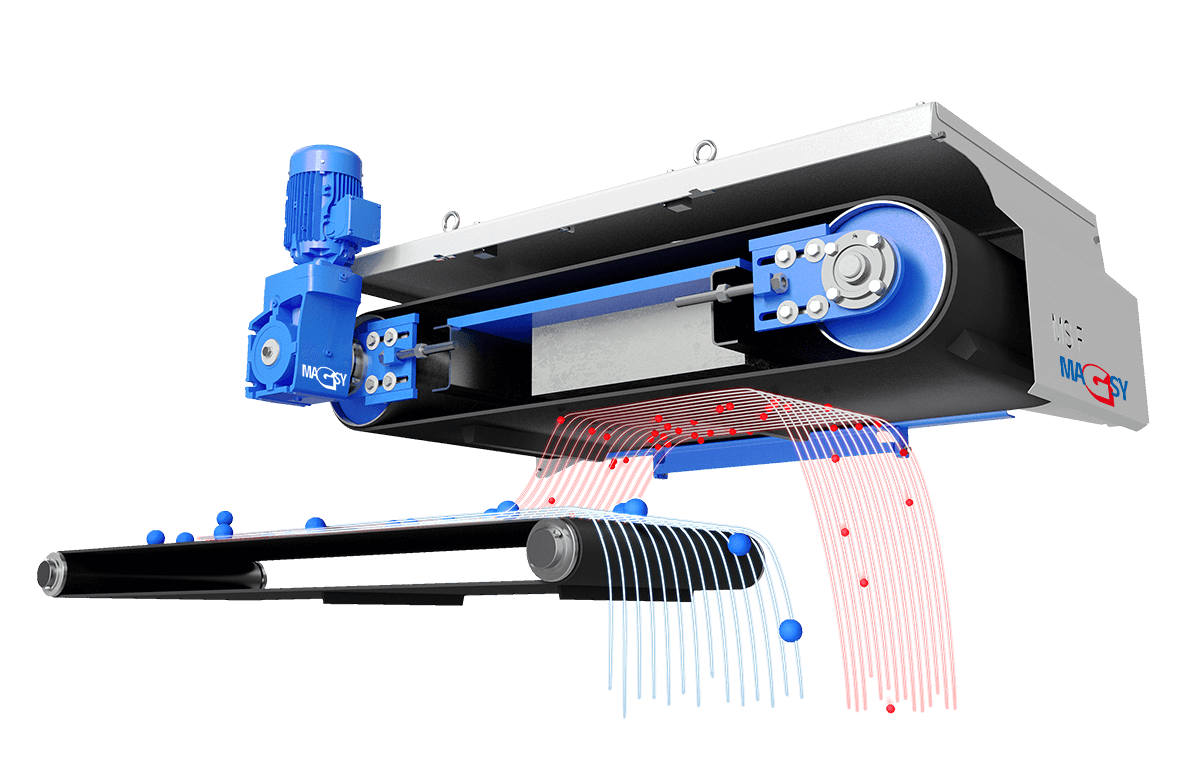

Design and cleaning principle of the separator

Important parts of the separator

High separation efficiency:

The magnetic conveyor can effectively separate ferromagnetic impurities from the material being transported, improving the quality of the final product and reducing the risk of damage to downstream processes.Automatic cleaning:

Many models are equipped with automatic cleaning mechanisms that periodically remove trapped debris from the magnetic system, minimizing the need for manual intervention and reducing maintenance costs.

Flexibility and easy integration:

Magnetic conveyors are designed to be easily integrated into existing conveying systems and can be adapted to different industrial applications such as recycling, food processing or building materials.Send us an e-mail

Aveți o întrebare sau sunteți interesat de o ofertă fără caracter obligatoriu?

Why Magsy

Own production hall

23 years on the market

Leading separator manufacturer in Europe

Service team 24 hours a day

Over 50,000+ separators produced

ISO 9001 certificates

How do we pack and ship magnetic separators?

How does the cooperation work?

Product Description

Separators situated above conveyors with an automatic cleaning are suitable on places where transportation using conveyor belts prevail, and where the material characteristics does not enable using another magnetic separation method.

Utilization areas- Municipality waste assortment

- Recycling and processing of derivative raw materials

- Other industrial areas where easily permeable materials are processed

Utilization areas in the industrial operations 1. Separation aimed at a processing technology protectionAs a partially limiting factor of using this separator situated above belt conveyors, maximum conveyor belt speed may be considered. The speed should not exceed 1.5 m/s. In case the speed is higher, do not hesitate to contact us.

...