Manual cleaning

What material do you separate

Vegetable oil

Sugar crystal

Poppy seeds

Grain

Rinsing baths

Sand

Plastic granulate

Syrup

Sunflower seeds

Cooling emulsion

Cooling oil

Sugar juice

Glaze

Gum

Rubber recyclate

Yoghurt

Ceramic mass

Ketchup

Spices

The above materials are only selected examples, consultation for your specific case is always important.

Contact us

Do you have a question or are you interested in a no-obligation quotation?

Magnets to injection molding machine hoppers

What is the separator suitable for?

-

- For dry bulk mixtures (regranulate, crushed material...)

- Suitable for placement in any conical hopper with a diameter of up to 420 mm

- Magnetic cores in the tube - easy cleaning and long life

- Strong neodymium magnets that capture even very small metallic impurities

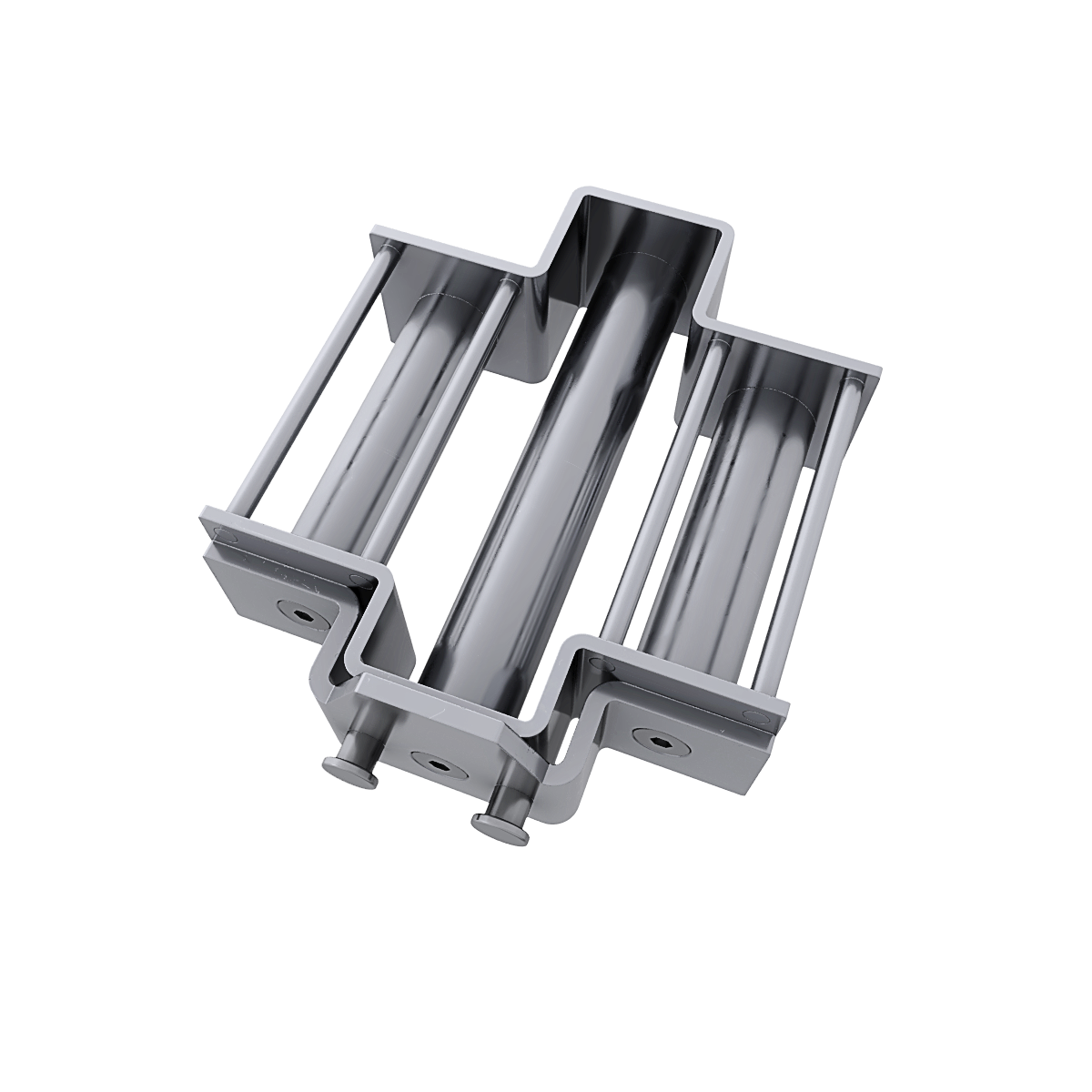

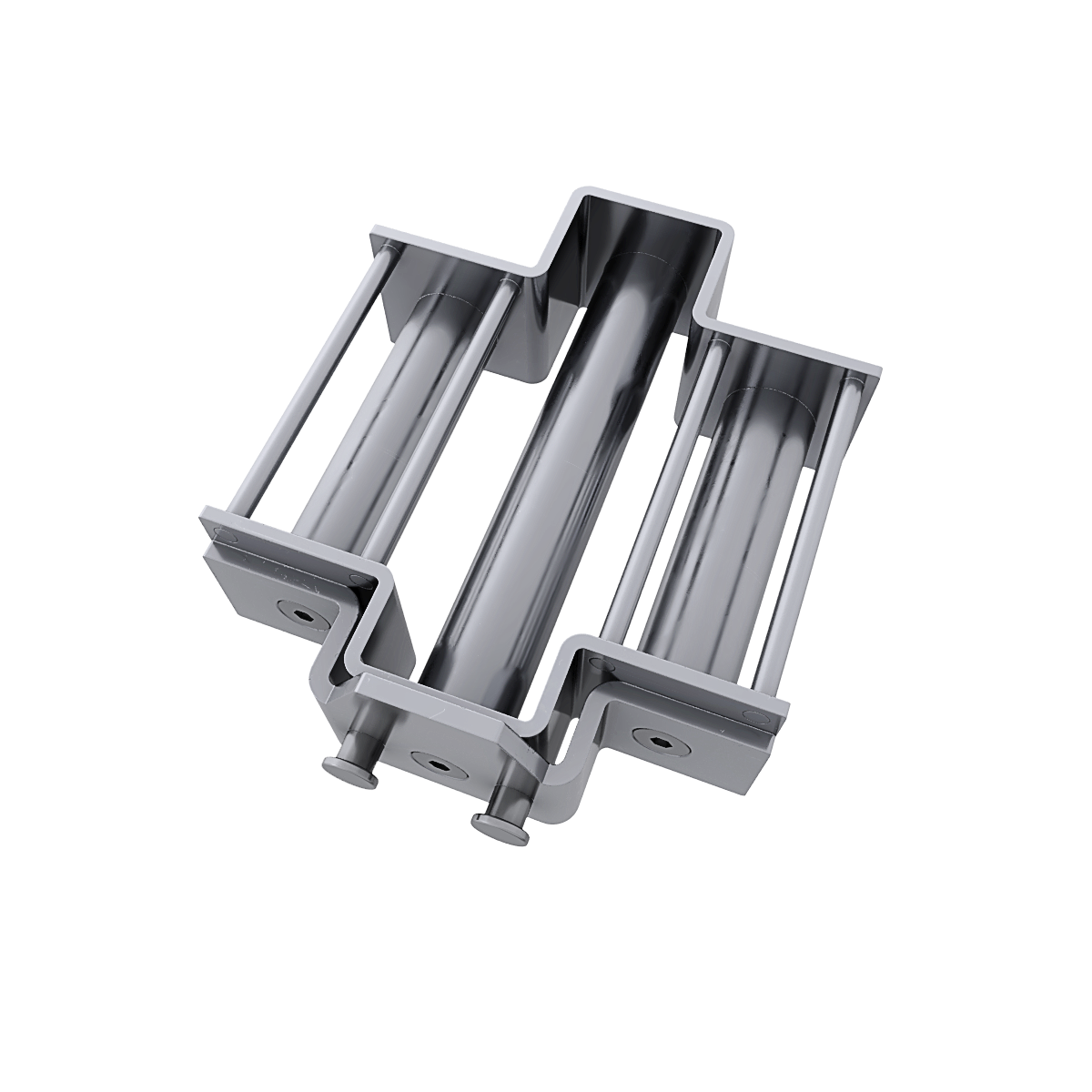

Design and cleaning principle of the separator

Important parts of the separator

Strong magnetic core

Contains high-performance neodymium magnets that effectively trap even fine ferromagnetic contaminants, protecting the injection moulding machine from damage.Compact design for easy installation

The magnet is designed to be quickly and easily placed directly into the hopper without the need for complex equipment modifications.

Durable stainless steel construction

Made of stainless steel to ensure long life and reliability in continuous operation.Send us an e-mail

Aveți o întrebare sau sunteți interesat de o ofertă fără caracter obligatoriu?

Model series

Why Magsy

Own production hall

23 years on the market

Leading separator manufacturer in Europe

Service team 24 hours a day

Over 50,000+ separators produced

ISO 9001 certificates

How do we pack and ship magnetic separators?

How does the cooperation work?

Product Description

Using the magnet in an injection molding machine hopper, injection molding nozzle lifetime may be increased significantly, saving thus big costs corresponding otherwise to the nozzle replacement. A great advantage consists in a possibility of a simple de-magnetizing by releasing of a safety screw and pulling the magnetic cores out of the stainless steel pipes.

We manufacture the models with the diameters ranging between 100 and 350 mm (the diameter of a circle drawn around the magnet).

InstallationA magnet to be used in an injection molding machine hopper may be placed simply to any conical hopper. According to its diameter, the magnet accommodates respective space in a certain hopper height on its sides.

Magnet typesThese are very strong neodymium NdFeB magnets based on rare earths; magnetic rod diameter is 22 mm.

Temperature resistance of the magnets80 or 120 °C

...Using the magnet in an injection molding machine hopper, injection molding nozzle lifetime may be increased significantly, saving thus big costs corresponding otherwise to the nozzle replacement. A great advantage consists in a possibility of a simple de-magnetizing by releasing of a safety screw and pulling the magnetic cores out of the stainless steel pipes.

Size models

We manufacture the models with the diameters ranging between 100 and 350 mm (the diameter of a circle drawn around the magnet).

Installation

A magnet to be used in an injection molding machine hopper may be placed simply to any conical hopper. According to its diameter, the magnet accommodates respective space in a certain hopper height on its sides.

Magnet types

These are very strong neodymium NdFeB magnets based on rare earths; magnetic rod diameter is 22 mm.

Temperature resistance of the magnets

80 or 120 °C

Separator material used

Stainless steel 1.4301 /AISI 304/

Ask us – we will advise you!

Made-to-measure production is our strength.

Magnets to be used in injection molding hoppers – new UP design

A new, improved magnet design to be used in injection molding machine hoppers has been developed based on requirements and experience of our customers. The main difference in comparison with the standard stainless steel version consists in the fact that magnetic cores are located in a plastics corpus made of ABS (Acryl-Butadiene-Styrene) material. The plastics corpus covers the whole hopper diameter so it is warrantied that all of the material falls through the magnetic pipes (i.e. removal of “deaf” places in the standard, stainless steel version where the metals may fall down on the magnetic separator sides).

Magnetic cores are connected to the plastics corpus that leads to an improvement of the working safety during the magnet cleaning (there is no risk of injury on own magnetic core handling). Even better safety may be achieved using a universal cleaning preparation.

Magnet cleaning is performed by pulling the magnetic cores out of the plastics pipes.

Size models

Plastics corpuses are manufactured in four size versions 280, 320, 390 and 425 mm.

Installation

Place a magnet to be installed into a hopper simply to any conical hopper. Based on its diameter, the magnet accommodates an appropriate space in a certain hopper height on its sides.

Magnet types

These are very strong neodymium NdFeB magnets based on rare earths; magnetic rod diameter is 22 mm.

Magnetic separator temperature resistance

70 °C

Separator material used

Plastics corpus is made of ABS (Acryl-Butadiene-Styrene) material.

ABS material is characteristic by a good temperature shape stability, and it has a high impact resistance even at low temperatures. It is hard and scratch resistant. It is not soaking excessively, and it has a good dimensional stability. It may be used in the temperature range of -50 °C to +70 °C.

Its disadvantages consist in a lower resistance against atmospheric factors, and conditional resistance against acids and alkalis.

ABS is commonly used in a production of automotive components, in the food industry and in the cold storage technology.

Ask us – we will advise you!

Made-to-measure production is our strength.

Magnet to be used in an injection molding hopper on a cleaning preparation

First of all, you need a cleaning agent hung on a wall. Then, using hooks, a magnet to be used in an injection molding hopper is installed. Metals caught will be removed easily.

Magnet to be used in an injection molding hopper – examples

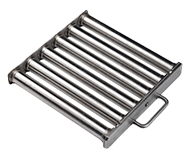

Magnetic grate with telescopic MR cores

Independent magnetic grates are manufactured by the company MAGSY especially per order, according to dimensions given by a customer.

Size models and magnetic grate designs

As a standard, MAGSY manufactures the MR and MRD magnetic grates with the pipe diameter of 31.0 mm. As an option, per customer request, MAGSY is capable of manufacturing also grates with pipes with the diameter of 25.0 mm. Magnetic grate lengths and widths are given by customer submission requirements.

- MG grates are manufactured for the pipe sizes ranging from 100 to 400 mm.

- MGD grates are produced for the pipe sizes ranging from 100 to 150 mm, by weight reasons.

Magnetic grates are used within the material flow. They are located either separately, or, at better, as a part of the complete case separator MSV. Magnetic grates are the crucial part of the case magnetic separators in loose materials. Magnetic output of the cores is set according to the submission and aim of a given separation task. To achieve an efficient separation, magnetic grates are used in two (or even more) floors located above each other, in order to provide a proper fall labyrinth.

Magnetic grate utilization – industrial areas

In the separation, magnetic grate(s) is/are used in all industrial areas where a dry material is separated in small or fine fractions, with good bulk parameters.

Areas of utilization:

- Food industry, feeding product industry

- Building matter industry, ceramics, porcelain production, chemical industry

- And other industrial areas where dry, loose / bulk materials are processed

Magnetic grates are not suitable for using with abrasive agents (pipe wall is machined to a small thickness of ca 0.6 mm = fast wearing out). The same applies to materials with adhesive characteristics (grates are stationary = there is a risk of separator clogging by the reason of so called “arching” of the material).

Areas of utilization in the industrial operations:

1. Separation used to protect technologies in operations:

Technology protection separation is aimed at ferromagnetic particle removal from a medium. The purpose consists in a protection of own technological devices against damaging (cutting knives, etc.). Magnetic grate(s) is / are located within the medium processing, before the technological units that need to be protected against damaging by Fe particles. To achieve the maximum output, magnetic cores of the grates are equipped with strong NdFeB magnets. Their composition or the core assembly is made to catch medium-size, small and fine impurities (up to the size of 1.0 mm) that could damage subsequent technological units. It means that, in practice, core compositions of the levels I or II are used.

2. Product cleanliness separation:

The aim of separation is cleaning of the own product from the ferromagnetic impurities, aimed at as good as possible product cleanliness. In this case, the grate (s) is/are situated especially on the end of the production process, or within its course, on more positions. From the output point of view, grate magnetic cores are equipped with the strongest NdFeB magnets, and the magnetic core composition is designed to catch fine to the smallest impurities (starting since 1,0 µm). In practice it means that core compositions on the levels III, IV, V or VI are used.

Main benefits of MG and MGD magnetic grates:

- Good separation level – using of the strongest NdFeB magnets and lowering of the magnetic force loss by an accurate core covering pipe to the thickness of 0,6 mm at max.

- Adjustable level of the core magnetic equipment on the levels I, II, III, IV, V or VI. – a proper separation task solution as a function of operational conditions and the separation target.

- User friendly cleaning system – the system of cores capable of being pulled out of the grates provides a possibility of a comfortable and good system of the grate cleaning from Fe impurities, enabling thus reduction of operator working time losses. However, from the working safety point of view we must be careful when handling the grates and cores in the pulled out state. Not careful handling means a danger of hand finger injury.

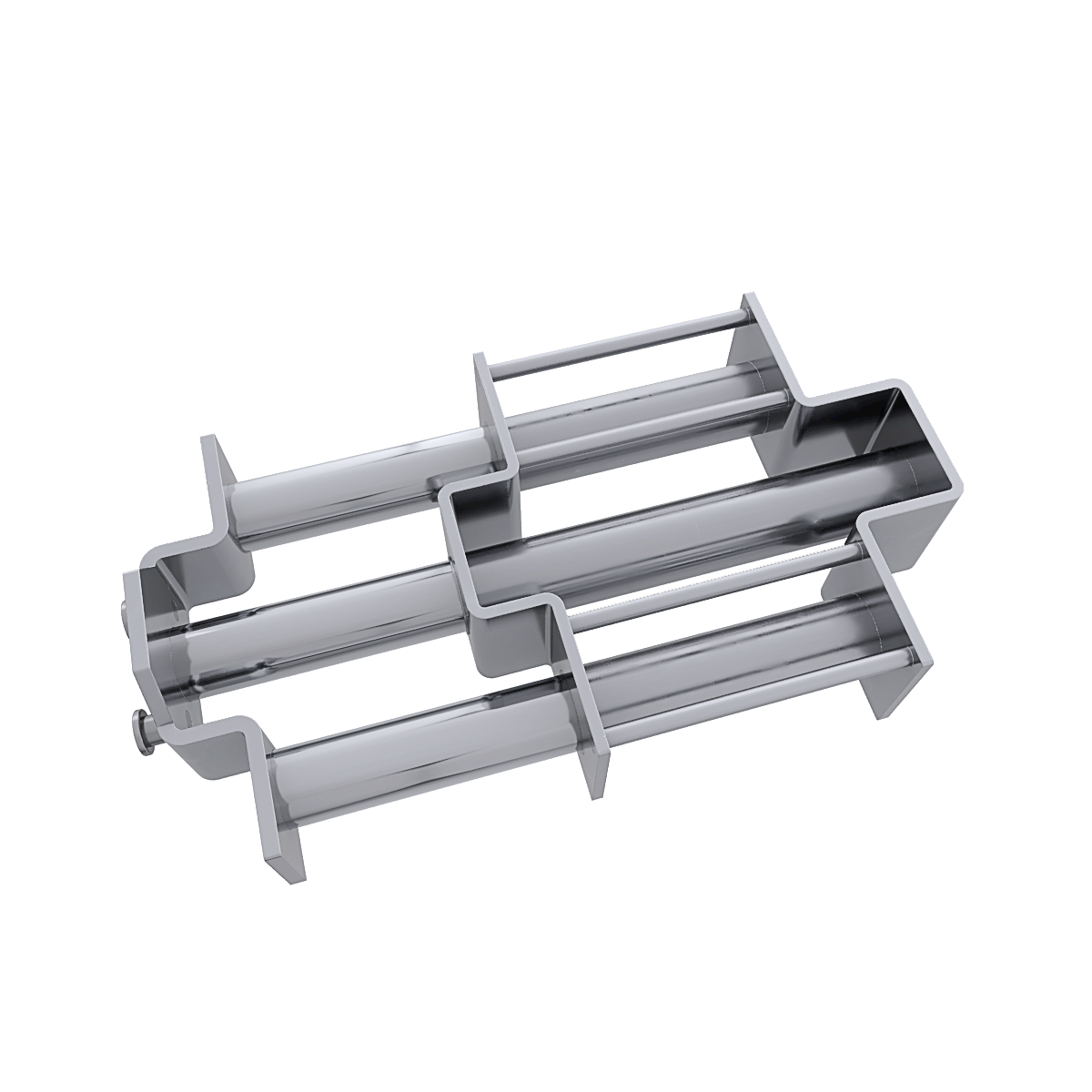

Magnetic grate design

Magnetic grates consist of the load-bearing frame, pipe cases and magnetic core. The load-bearing frame for pipes is made of a flat profile with the thickness of 40 mm.

The pipe or the magnetic core cases are made of pulled, seamless pipes, and they are engineered to a very low thickness (ca 0.6 mm), providing magnetic output losses as low as possible. The standard MAGSY grate pipe diameter is 31.0 mm.

Grate magnetic equipment, the core

Magnetic core consists of round magnets (circular profile) and pole distances. The assembly of magnets and pole extensions is defined by carrying-away rods characteristic by a round profile. Magnetic material type and core composition are given by the requirement on the magnetic output value. At present, mostly neodymium NdFeB magnets are used for the cores. Ferrite magnetic cores have significantly lower magnetic power, so recently they are used just rarely.

Dropping labyrinth

An efficient function of all grate-type separators is based on:

- The sufficient magnetic induction (Gs) on the surface and near the grate pipes

- The high tear-off force (N) on the own grate pipe surface

- The proper, efficient dropping labyrinth of the grate pipes within a medium flow

Due to that, any impurity must be got to a contact with the magnetic pipe, or to its immediate proximity. By that reason, magnetic grates must be located on two levels located above each other at least, in order to guarantee that separate pipes of both of the grates mutually form an efficient dropping labyrinth.

Warning

Because of the fact that separate magnetic grates are supplied per order, the question of so called “dropping labyrinth” is not solved by the MAGSY side. This indispensable condition of the separation proper functioning is solved and provided by the MAGSY company only in cases of complete separators from the company portfolio (MSV, etc.)./strong>

Grate cleaning system

Magnetic grate cleaning is always manual. Both the grate frame and the core case made of pipes are manufactured using a stainless steel, in order to prevent self-magnetization.From one side the pipes are open in order to provide a possibility of a full magnetic core pulling out. On the frame where the cores are located, the frame profile is equipped with a safety clip preventing spontaneous core release from the grate. After the clip release, the cores may be fully pulled out

A possibility of the core pulling out of the cases brings about an assumption of the grate de-magnetizing that is a condition of a comfortable grate cleaning from separated magnetic impurities.All magnetic grates require a regular manual cleaning from the magnetic impurities. Cleaning frequency cannot be stipulated generally. It always depends on the size of respective portion in the medium. Grate cleaning interval must be adapted to the value as any excessive deposit of impurities on the grate pipes significantly reduces the separation efficiency.

Cleaning preparations and grate aids

MAGSY, as a manufacturer of separators, is strongly focused on the improvement of magnetic grate cleaning comfort. To simplify the own grate cleaning process, MAGSY produces the cleaning aids that are offered as auxiliary equipment to separator sets. Cleaning aids serve to simplify the cleaning process, improve the cleaning comfort, and also to improve the working safety on magnetic grate handling. The material: stainless steel sheet metal 1.4301.

MAGSY recommends cleaning preparation using for separator cleaning..

Cleaning preparation working steps

- Attach the grate with cores to the holder situated on the cleaning preparation (No. 1)

- After the clip (No. 2) has been released, the cores are pulled out of the grate (No. 3)

- Separate cores, pulled out of the grate, are stored in a self-contained compartment (No. 4) where they are protected against own damaging and pollution and, at the same time, they are thus secured from injury point of view.

- An independent, empty grate is then without a magnetic field, so Fe impurities leave it freely into the garbage basket. Residual impurities can be wiped-off then easily by a brush.

Cleaning preparation usage:

- cleaning comfort is increased

- improves the working safety

- increases the magnetic core lifeti

To further increase the working safety on the grate cleaning, MAGSY manufactures special cleaning aids.

General technical specification of MG, MGD magnetic grates:

Magnetic equipment

- very strong NdFeB magnets located in the covering pipes.

- As a standard: round magnet, outer diameter Ø 29 mm, pipe outer diameter Ø 31 – 32 mm

- As an option: round magnet, outer diameter Ø 24 mm, pipe outer diameter Ø 25 mm

Magnetic material temperature resistance

- As a standard: up to 80 ˚C

- As an option: up to 150 ˚C (or even higher)

Magnetic power (output)

Grate system

- Stationary grates, pulling-out magnetic cores

Dropping labyrinth

- Recommendation: magnetic grates, at least on two stages

Grate and covering pipe material

- As a standard: stainless steel 1.4301 / AISI 304.

- As an option: stainless steel 1.4404 / AISI 316L

All materials are quality-certified according to EU norms.

Surface treatment

- Grate frame: machine blasting using ceramics compound

- Outer pipe surface: machine blasting or, as an option, polishing

Connecting elements

- Designed separately by a customer

Engineered processing

All engineering operations are carried out on own machines, using own MAGSY CZ engineering technology.

Component welds

Component welds are performed according to requirements of technological norms valid for stainless steel material welding. Demanding outgoing weld quality inspection ensures the high outgoing quality.

Ask us – we will advise you!

Made-to-measure production is our strength.

Double-level magnetic grate situated within a pipeline

Size models:

- As a standard, we manufacture this grate for pipelines with the diameter of 300 mm

Installation

Weld the upper part of the pipeline to the pipeline ending. Using a quick-acting clip, on the lower part of the pipeline where the magnetic grate is situated, attach a large-volume for cleaned material packing.

Magnetic rods – the main benefits

- Sufficient magnetic output for the testing of magnetic impurities

- Possibility of using with dry mixtures

- High separation level – the strongest NdFeB magnets are used; magnetic force loss is reduced due to a precise machining of the magnetic rod covering pipe, to the thickness of 0.6 – 0.7 mm at maximum.

- To the pipeline end, a large-volume bag may be attached quite simply.

Magnetic rods – industrial utilization areasí

Using in dry materials

In general, magnetic grates may be used in all industrial areas where dry, homogeneous materials are to be cleaned, or dry material mixtures in small to very fine fractions with good loose parameters need to pass through the process

Grates consisting of magnetic rods are not suitable to be used with abrasive matters because the rod wall is machined to a small thickness so it may become worn out very soon. Adhesive materials are not suitable neither. The grates formed by rods are usually stationary, i.e. there is a risk of grate clogging due to so called material “arching”.

Utilization areas

- Agricultural product industry, feeding mixtures, food industry

- Production of building matters, ceramics and porcelain manufacturing, chemical industry

- Plastics and rubber processing industry, and other industrial areas where dry materials with good loose characteristics are processe.

Magnetic grate general technical specification

Magnetic equipment

- Very strong NdFeB magnets

- Magnetic core Ø= 29 mm,

- Covering pipes Ø=30 mm

- Temperature resistance of the magnetic material: up to 80˚C as a standard

- As an option: up to 120˚C (or, possibly, even higher temperatures)

Magnetic output

Grate system

- Magnetic core is closed in a rod; the core cannot be pulled out

Dropping labyrinth

- Magnetic grates form a double-level dropping labyrinth (4+3). The upper row, consisting of four rods, is characterized by the outer rod spacing of 65.3 mm and the inner rod spacing of 69.4 mm. The lower rod row has a unified spacing of 66 mm. The height-defined distance between both of the rod rows is 69 mm.

Rod design

- Closed rod, rod wall is machined to the thickness of 0.6 mm at maximum.

Grate cleaning technique

This magnetic grate only consists of closed magnetic rods, not pipes with cores disposing of pulling capability. Magnetic rod cleaning is performed manually, by wiping Fe impurities off the rod surface.

Magnetic grates require regular manual cleaning from the magnetic impurities. The cleaning frequency cannot be stipulated generally. It always depends on the size of Fe impurity portion in the medium in question. Grate cleaning interval must be adjusted to that value because each excessive impurity deposit on the grate rods reduces significantly the separation efficiency. Because of that, magnetic grates are recommended for using in discontinuous operations only, where regular, sufficiently frequent grate rod manual cleaning can be provided.

Rod material

- As a standard: stainless steel 1.4404 / AISI 316

- All materials in the quality according to respective EU standards, with appropriate certifications

Surface treatment

- Outer rod surface is treated by polishing

Grate attachment within a pipeline

The grate design allows for its fast assembling and disassembling, by inserting into the bayonet groove, and rotating (securing) of the working position.

Connecting elements

- The pipe to be welded, or JACOB clips

Engineering workmanship

All engineering workmanship and machining operations are carried out using machines belonging to own MAGSY manufacturing equipment, using own engineering technology, own MAGSY CZ machines belonging to a modern MAGSY CZ machinery park.

Component welds

They are performed according to requirements of technological standards valid in stainless steel material welding. Demanding outgoing weld quality inspection guarantees a high outgoing product quality.

Ask us – we will advise you!

Made-to-measure production is our strength.