Automatic cleaning

What material do you separate

Flour

Sugar crystal

Ground paprika

Poppy seeds

Grain

Sand

Plastic granulate

Beet pulp

Sunflower seeds

Shot

Spices

The above materials are only selected examples, consultation for your specific case is always important.

Contact us

Do you have a question or are you interested in a no-obligation quotation?

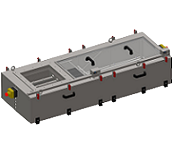

Plate magnetic separator

What is the separator suitable for?

-

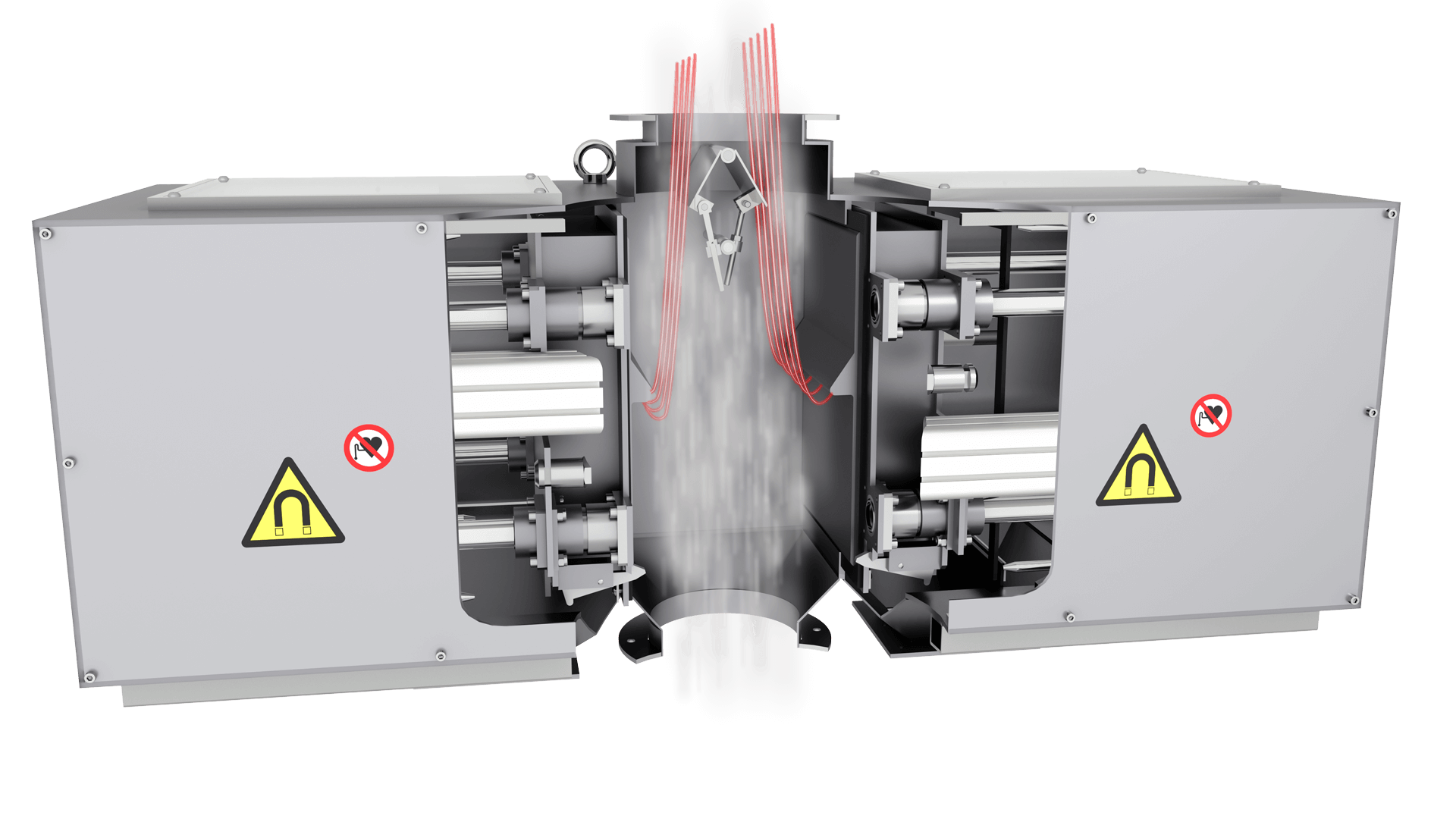

- Effectively picks up fine metal contaminants from loose and abrasive materials.

- Suitable for chutes and piping systems

- Protects machinery and enhances product quality

- Magnetic plate with high induction up to 12,000 G

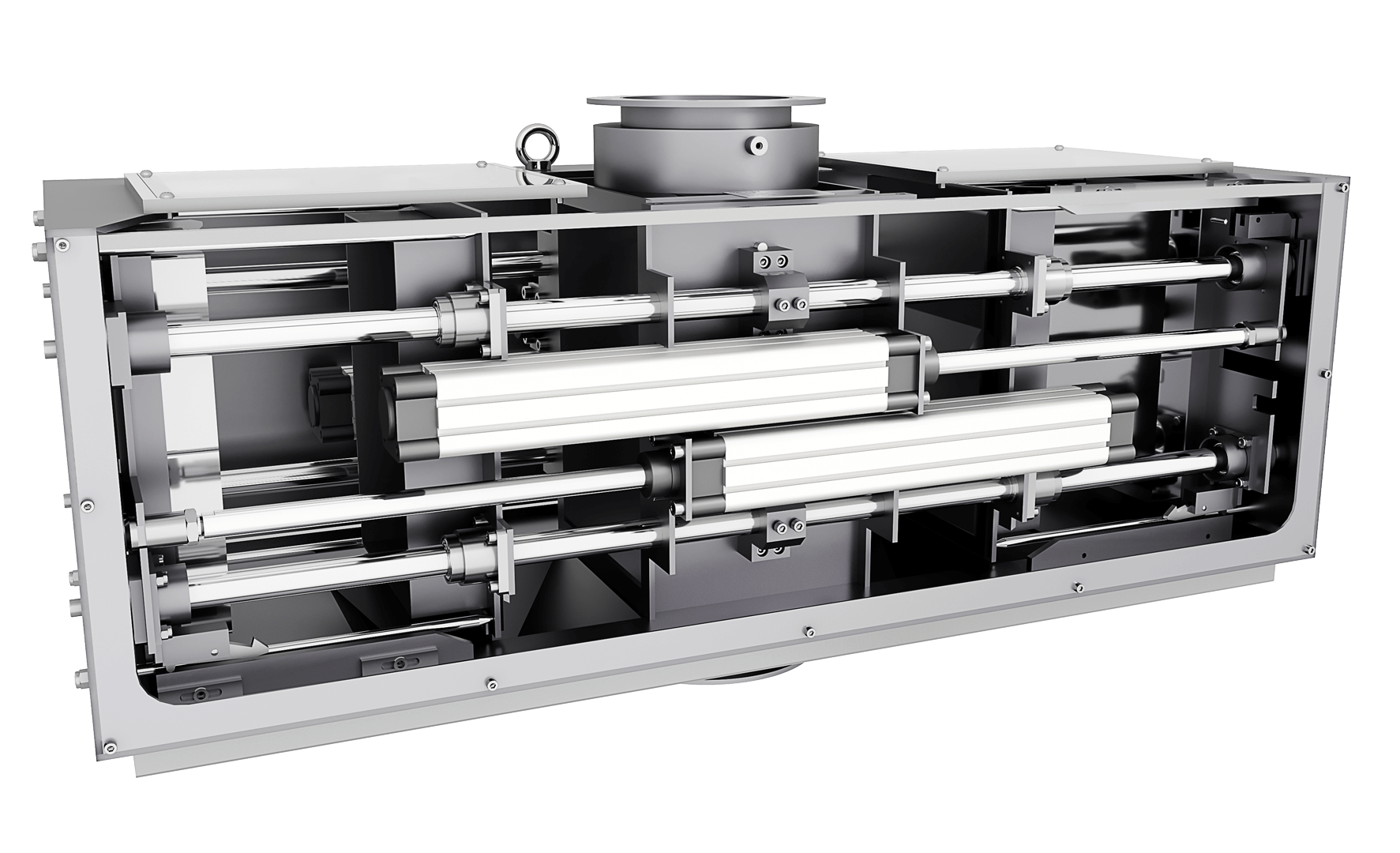

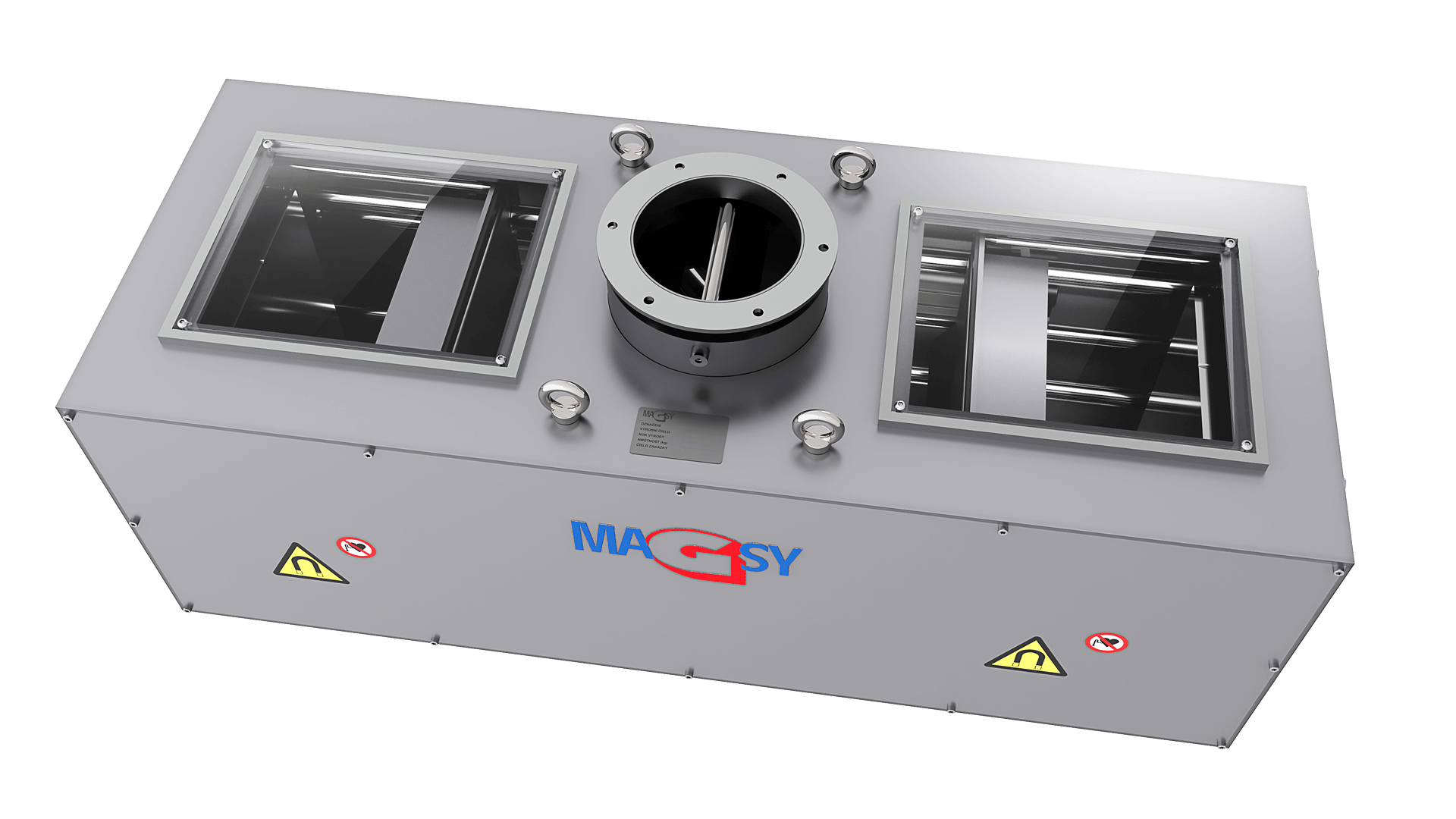

Design and cleaning principle of the separator

Important parts of the separator

Magnetic plate with protective poles and inlays

The magnetic plate is equipped with protective poles against abrasion and lined with abrasion-resistant polyurethane, which is suitable for food applications.Cleaning automation

A fully automated cleaning process increases productivity, eliminates the need for manual operators and prevents human neglect of cleaning intervals.Send us an e-mail

Aveți o întrebare sau sunteți interesat de o ofertă fără caracter obligatoriu?

Model series

Why Magsy

Own production hall

23 years on the market

Leading separator manufacturer in Europe

Service team 24 hours a day

Over 50,000+ separators produced

ISO 9001 certificates

How do we pack and ship magnetic separators?

How does the cooperation work?

Product Description

MSP FAC is used to protect both the process equipment (ferrite core design) and to control and secure the final product (neodymium core design).

The high magnetic performance together with the perfect processing and cleaning system meet the needs of the most demanding customers in various industries where high requirements are placed on the protection of process equipment and the purity of the final product.

...