Manual cleaning

What material do you separate

Flour

Plastic granulate

Soot

Sugar meal

Kaolin

The above materials are only selected examples, consultation for your specific case is always important.

Contact us

Do you have a question or are you interested in a no-obligation quotation?

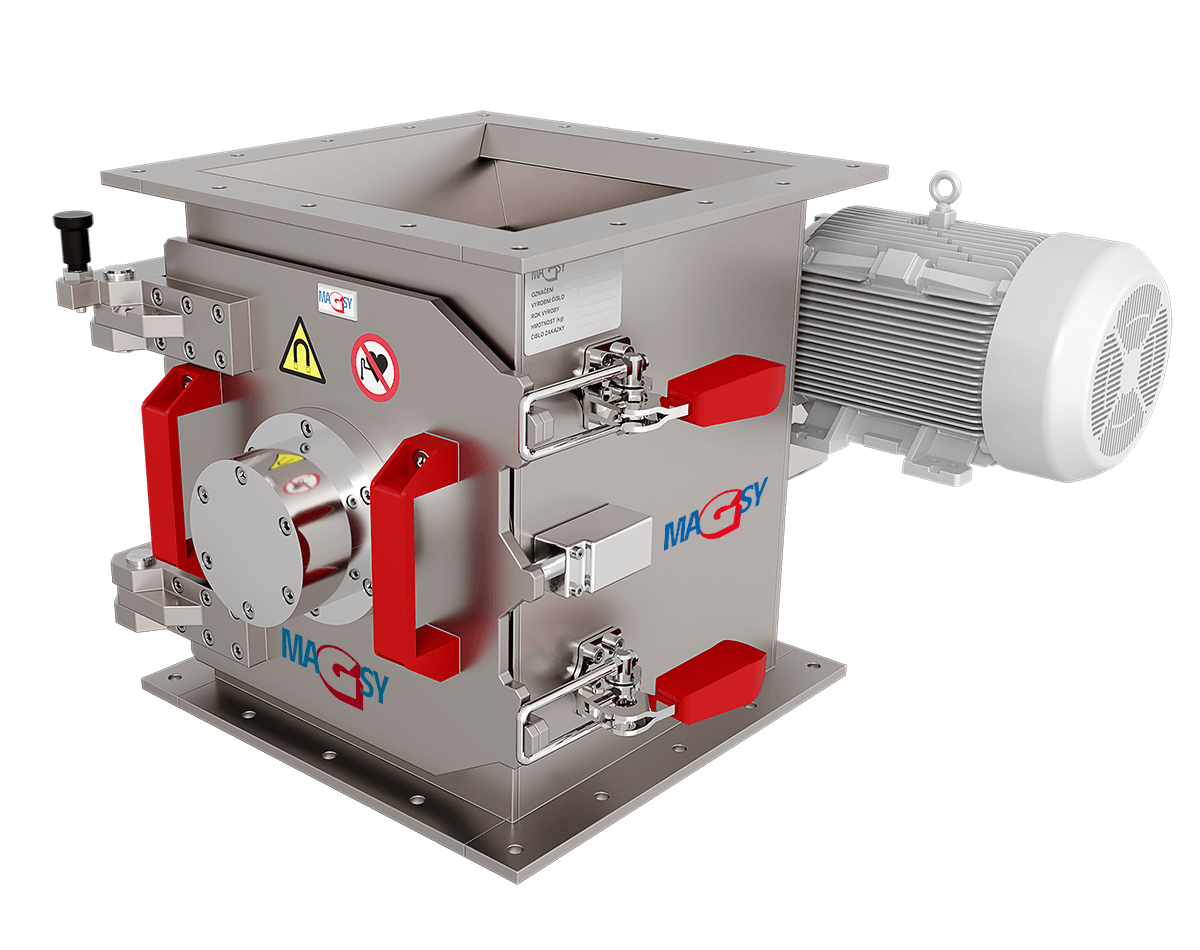

Rotational magnetic separator

What is the separator suitable for?

-

- For loose abrasive materials that tend to arch

- Captures dirt from 1.0 µm in size

- Magnetic induction up to 17,000 G

- Thanks to the rotation of the magnetic cores - reliable separation

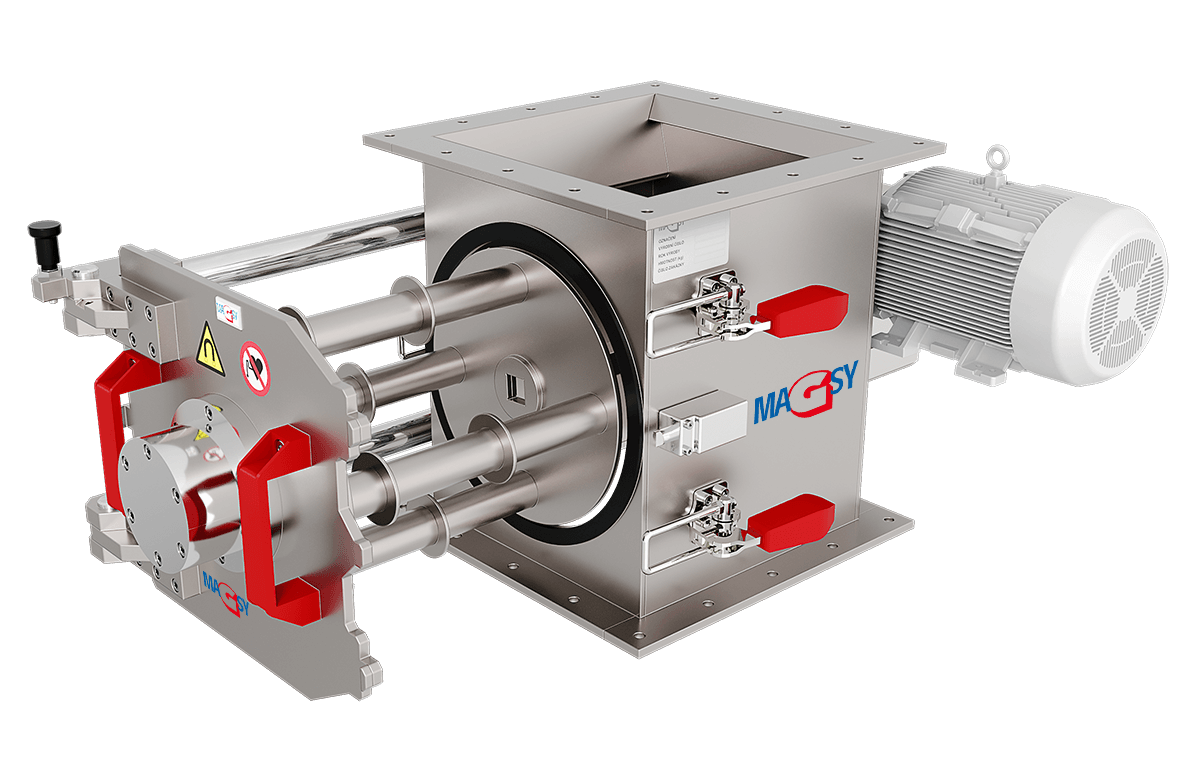

Design and cleaning principle of the separator

Important parts of the separator

Rotary magnetic system

The rotating magnetic bars ensure uniform exposure of the material to the magnetic field, increasing the separation efficiency even for poorly flowable or sticky materials.High performance neodymium magnets

Strong magnets trap even very fine ferromagnetic impurities, protecting the equipment and enhancing the quality of the final product.

Durable stainless steel construction

Stainless steel construction ensures long life and corrosion resistance, suitable for the food and pharmaceutical industries.Automatic or manual cleaning system

The choice of manual or fully automated cleaning increases flexibility and facilitates maintenance according to operational needs.

Send us an e-mail

Aveți o întrebare sau sunteți interesat de o ofertă fără caracter obligatoriu?

Model series

Why Magsy

Own production hall

23 years on the market

Leading separator manufacturer in Europe

Service team 24 hours a day

Over 50,000+ separators produced

ISO 9001 certificates

How do we pack and ship magnetic separators?

How does the cooperation work?

Product Description

Industrial areas of MSVR separator utilization

Practically, MSVR may be used in all industrial areas where materials characterized by fine to very fine fractions with compromised loose parameters, are separated.

Utilization areas:- Food industry

- Building matter production

- Ceramics industry

- Chemical industry

- Plastics and rubber processing, waste recycling and processing

- And other industrial areas where materials with compromised loose parameters are processed.

To a limited extent, MSVR rotational magnetic separator is useful also in slightly abrasive materials. However, in such case there must be considered the reduction of

magnetic induction (magnetic force) in tens %. For each magnetic force level, this reduction is different.

Why should these magnetic separators be used? ...Industrial areas of MSVR separator utilization

Practically, MSVR may be used in all industrial areas where materials characterized by fine to very fine fractions with compromised loose parameters, are separated.

Utilization areas:

- Food industry

- Building matter production

- Ceramics industry

- Chemical industry

- Plastics and rubber processing, waste recycling and processing

- And other industrial areas where materials with compromised loose parameters are processed.

To a limited extent, MSVR rotational magnetic separator is useful also in slightly abrasive materials. However, in such case there must be considered the reduction of

magnetic induction (magnetic force) in tens %. For each magnetic force level, this reduction is different.

Why should these magnetic separators be used?

-

Due to very strong magnets, you protect your technologies:

This separation is aimed at ferromagnetic impurity removal from the material, in order to protect subsequent technological units (grinders, mills, extrusion heads, etc.) against their fatal damaging. From the output point of view, rotating component magnetic cores are equipped with strong NdFeB (neodymium) magnets assembled to a magnetic circuit capable of catching medium-size, small to fine metal magnetic impurities (the size from 1 mm) that could damage your technological device. In these magnetic assemblies, level I .is applied.

-

Product cleanliness separation due to the extra strong magnetic field assembly:

Product-cleanliness separation focuses on a perfect cleaning – own product separation from the ferromagnetic impurities purposed at achieving of as good as possible product cleanliness. In this case, we mostly recommend installing the magnetic separator as a final, ending position, before the point where the material leaves the plant. To achieve as much as possible magnetic separation efficiency, we recommend choosing one more place of the installation, somewhere during the course of the production. This is the most efficient technique. In case of this magnetic separation, we used the strongest possible magnetic circuit assembly, i.e. level II. ,where the finest metal magnetic impurities up to the size of 1,0 µm are caught.

Separator safety and quality information

We care about the high quality of our magnetic separators

Technical solution

Through the magnetic separator, the material is passing using the gravity principle that is the same as with e.g. magnetic separators with telescopic grates; metal magnetic impurities are caught on magnetized pipes arranged into a circular assembly. It is exactly this kind of rotation that provides the material is moved uniformly through the pipeline, preventing thus magnetic separator clogging given by worsened loose parameters of the separated material. In some cases this rotation is even a positive factor in relation to other technological devices and material processing (the material is aerated – ruffled).

In various material types it is necessary to choose different magnetic component rotational speeds, so we standardly offer our rotational magnetic separators either with one or with two adjustable speeds. As an option, the device may be supplied also with a fluently regulated speed.

By the reason of its cleaning, it is necessary to count with a short material flow interruption with this magnetic separator type. The flow interruption varies according to a selected rotational separator type (STANDARD, ECO, STANDARD – UP, AUT). In case the material flow interruption is not possible from a technological reason, we recommend installation of a bypass where simplest magnetic separator may be installed to the other branch, to provide a continuous, uninterrupted separation.

MSVR magnetic separator structural solution

From the structural point of view, this magnetic separator consists of the magnetic separator body and of so called circular assembly of magnetic cores, located in stainless steel pipes. Together they form a magnetic component (magnetic core magnets temporarily the stainless steel pipes). This magnetic component rotates around its axis, as a whole. Magnetic separator is installed in the vertical position at best, within the poured material free fall. Circularly arranged covering pipes are – by the reason of possible current wear and tear – replaceable. Wear and tear may also take place in cases when the separator is installed into slightly abrasive materials (prior to its using in this abrasive environment, the manufacturer must be consulted).

Magnetic cores form a strong magnetic field in which metal magnetic impurities are attracted to the pipe surface where they remained firmly attached. Magnetic function of these magnetic separators is based on

the strong magnetic induction and tear-off force values on a the own covering pipe surface. Therefore, any impurity must be taken to a close contact with the magnetic pipe, or to its immediate proximity.

This magnetic separator is equipped with driving units made by reputed companies NORD or SEW. Gear ratios are designed depending on a type of material from which the separation will take place. Magnetic separator control is provided either using a separate distributor meeting all demands and requirements of European norms, or it is ended with a terminal box located on the motor (it always depends on a specific customer requirement – whether they require a complete solution, or if they want to install the entire device and connect it to their technological system).

Ask us – we will advise you!

Made-to-measure production is our strength.

Type designation and the product line:

MAGSY manufactures the following magnetic separator type, in four designs:

- MSVR Standard

- MSVR EKO

- MSVR Standard – UP

- MSVR AUT

Each of the groups consists of several models, according to the magnetic separator size. Separate MSVR product groups vary according to customer needs, especially in relation to the magnetic force required, comfort level, cleaning system, and regarding the operator working safety level.

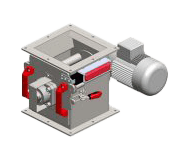

Rotational magnetic separator MSVR – EKO

Size models and the separator design

As a standard, MSVR ECO is manufactured for connecting to the square pipeline. In case the installation is performed with the round pipeline, suitable transition elements from the square to round pipeline should be supplied. By request, we would like to deliver you these elements.

MSVR ECO currently manufactured models and sizes

For the round pipelines with the dimensions: 200×200; 250×250 mm

If required so by customers (untypical mating dimensions, insufficient construction height), we will produce for you the MSVR ECO dimensionally modified according to your demands, as a custom-made item.

MSVR EKO separator main benefits

- Reliable separation – due to the magnetic core rotation, perfect dropping labyrinth is created

- High separation level – using of the strongest NdFeB magnets and reduction of the magnetic force loss by a precise machining of the magnetic core covering pipe, to the smallest possible thickness

- Adjustable magnetic core equipment level – levels I or II

- High engineering workmanship level – the best materials are used, there is a high engineering workmanship precision, resistance, durability, assembling readiness

- The simplest cleaning system from the user´s point of view – the system of telescopic magnetic cores, in a combination with stainless steel covering pipes, guarantees very fast and thorough cleaning process

- According to requested magnetic separation level, technology protection or product protection, magnetic core may be equipped with various magnetic circuit assemblies, namely on the two standardized level. Either there is preferred the magnetic induction value, or the tear-off force value need to be prioritized. According to these criteria,

- core composition on the levels I. to II. is selected.

Separator safety and quality information

We care about the high quality of our magnetic separators

MSVR EKO general technical specification

Magnetic equipment

- Very strong NdFeB magnets situated in the covering pipes

- Inter-circular magnet outer Ø= 29 mm, outer pipe Ø= 31-32 mm according to required magnetic output.

Magnetic material temperature resistance

- As a standard: up to 80 ˚C

- As an option: up to 150 ˚C

Magnetic output

by selection of the 2 levels, I – II according to the separation task and operational conditions

Grate system

- rotational, pulling-out cores formed by stainless steel covering pipes; the whole component is removable from the magnetic separator body to be comfortably and completely cleaned

Dropping labyrinth

- due to the rotating component, maximum dropping labyrinth is ensured

Case and magnetic component material

- as a standard: stainless steel 1.4301 / AISI 304

- as an option: stainless steel 1.4404 / AISI 316L (for acidic pH environments)

Door sealing material

- as a standard: rubber sealing in a quality corresponding to the separation task and operational conditions

- as an option: food industry sealing conforming to the food industry requirements

- All materials are quality-certified according to EU norms.

Surface treatment

- Outer case surfaces and grate frame: machine-blasted by a ceramics mixture

- Outer grate pipe surface: machine-blasted, or polished as an option

- Inner case surfaces are machine-blasted, in case of the food industry the corners and welds inside of the case are machined according to requirements of the food industry norms (as an option)

Connecting elements

- As a standard: flange according to an appropriate pipeline dimension

- Counter-flanges are parts of the product supply

Engineering workmanship

- Quality and precise engineering workmanship is guaranteed

- All engineering operations are carried out using machines of the own production facility and own MAGSY CZ engineering technology

Component welds

They are performed according to requirements of valid technological norms dealing with stainless steel material welding. Demanding outgoing weld quality control guarantees a high outgoing production quality.

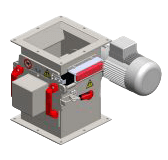

Rotational magnetic separator MSVR – Standard

Size models and the separator design

As a standard, MSVR STANDARD is manufactured for connecting into square pipelines. In case it is installed into a circular pipeline, suitable transitional elements from the square to circular pipeline must be supplied. Per your request, we would like to supply you those as well.

MSV Standard currently manufactured models and sizes:

For square pipelines with the dimensions of: 200×200; 250×250; 300×300; 350×350; 400×400 mm.

In case of customer requirements such as untypical mating dimensions, insufficient construction height, we will manufacture for you the MSV STANDARD dimensionally modified, according to your requirements, as a custom-made order.

Main benefits of the MSVR STANDARD separator:

- Reliable separation – due to magnetic core rotation, perfect dropping labyrinth is formed

- High separation level – by using the strongest NdFeB magnets and reduction the magnetic force loss due to the fact that magnetic core covering pipe was precisely machined to as small as possible thickness

- Adjustable magnetic core equipment level, in the quality I or II

- High engineering workmanship quality – we use the best materials, there is a high engineering workmanship precision, resistance, durability, assembling readiness

- User friendly cleaning system – a system of covering pipes to be pulled out of the magnetic cores using ergonomic cleaning jig

Based on required magnetic separation level, technology protection or product protection, magnetic cores may be equipped with various magnetic circuit assemblies, namely on two standardized levels. Either there is preferred magnetic induction value, or the tear-off force value needs to be prioritized. According to these criteria, core composition on the levels I. to II is chosen.

A great advantage during the magnetic component cleaning consists in the fact that magnetic cores are not pulled out of the stainless steel covering pipes, but, in case of our STANDARD solution, covering pipes are pulled down from the magnetic cores. This has a good impact onto the maximum working safety increase during the magnetic separator cleaning – in this case, magnetic cores cannot be put aside spontaneously so there is no risk of injury given by magnetic core „attaching“ to steel objects.

MSVR STANDARD general technical specification

Magnetic equipment

- Very strong NdFeB magnets placed in the covering pipes

- Circular magnet outer Ø= 29 mm, pipe outer Ø= 31-32 mm according to the magnetic output required

Magnetic material temperature resistance

- As a standard: up to 80 ˚C

- As an option: up to 150 ˚C

Magnetic outputn

- by selection of the two levels, I – II according to the separation task and operational conditions

Grate system

- Rotational, pulling-out covering pipe, stationary magnetic cores – fixed

Dropping labyrinth

- Due to the rotating component, the maximum dropping labyrinth is guaranteed

Case and magnetic component material

- As a standard: stainless steel 1.4301 / AISI 304

- As an option: stainless steel 1.4404 / AISI 316L (in acidic pH environments)

Door sealing material

- As a standard: rubber sealing in a quality corresponding to the separation task and operational conditions

- As an option: food industry sealing conforming to the food industry norms

All materials are quality-certified according to EU standards.

Surface treatment

- Outer case surfaces and grate frame: machine-blasted by a ceramics mixture

- Outer grate pipe surface: machine-blasted, or polished as an option

- Inner case surfaces are machine-blasted, in case of the food industry the corners and welds inside of the case are machined according to requirements of the food industry norms (as an option)

Connecting elements

- As a standard: flange according to an appropriate pipeline dimensions

- Counter-flanges are parts of the product supply

Engineering workmanship

- Quality and precise engineering workmanship is guaranteed

- All engineering operations are carried out using machines of the own production facility and own MAGSY CZ engineering technologies

Component welds

They are performed according to requirements of valid technological norms dealing with stainless steel material welding. Demanding outgoing weld quality control guarantees a high outgoing production quality.

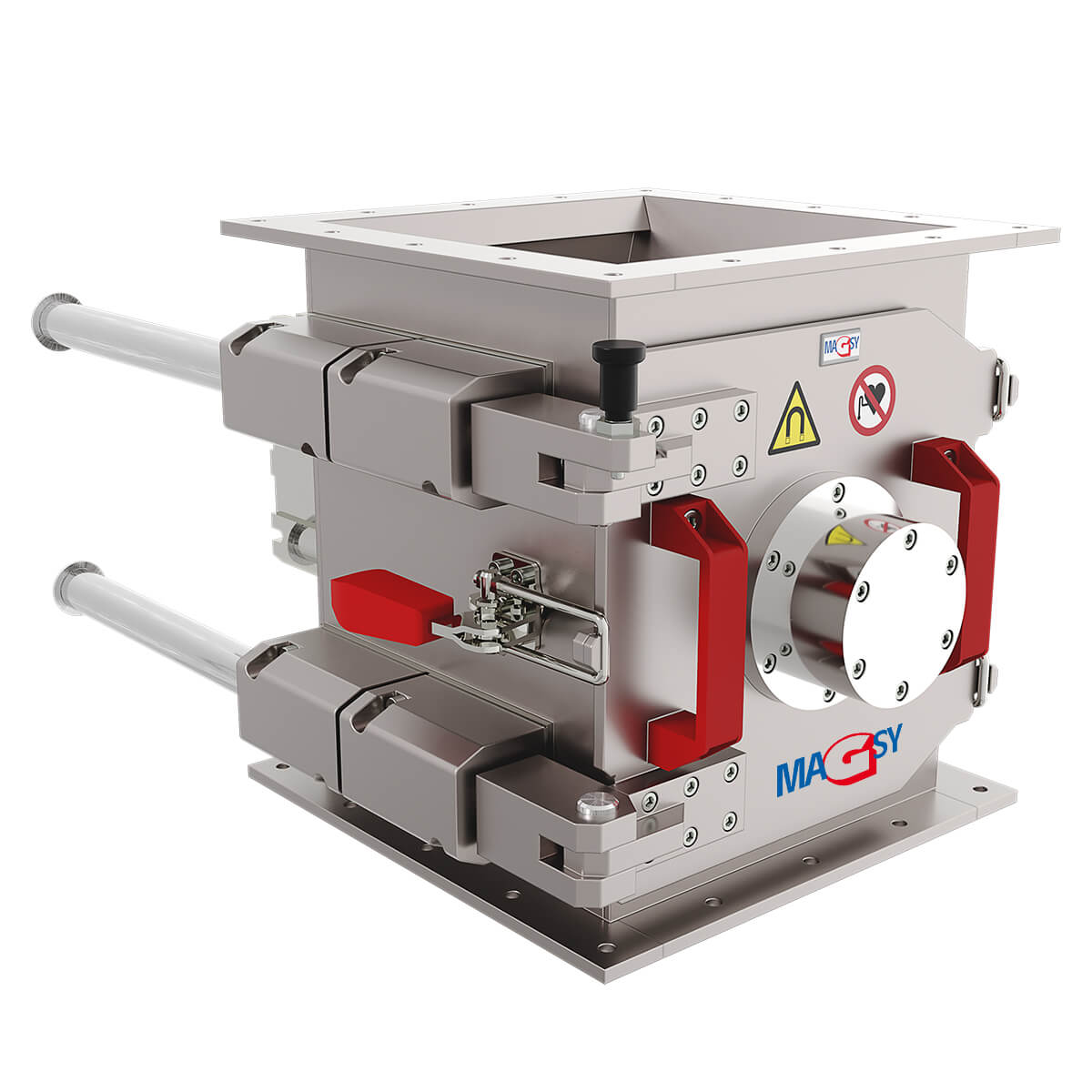

Rotational magnetic separator MSVR Standard – UP

Size models and the separator design

As well as the lower series STANDARD, MSVR STANDARD – UP is manufactured for connecting onto square pipelines. In case of an installation onto round pipelines, transition elements suitable for the square to round transition must be delivered. By request, we would like to supply you these transition elements.

MSV Standard – UP – currently manufactured models and sizes

For the square pipelines with the dimensions: 200×200; 250×250; 300×300; 350×350; 400×400 mm

If required by a customer (untypical mating dimensions, insufficient construction height), we will manufacture for you the MSV STANDARD – UP dimensionally modified according to your demands, as a custom-made commission.

Main benefits of the MSVR STANDARD – UP separator

- Reliable separation – due to the magnetic core rotation, perfect dropping labyrinth is created

- High separation level – using of the strongest NdFeB magnets and the magnetic force loss reduction by the magnetic core covering pipe machining to the smallest possible thickness

- Adjustable magnetic core equipment level – on the levels I or II

- Innovative solution of the whole system, including outstanding structural solution of the core covering – saving of operational costs of the device maintenance.

- Compact device, magnetic cores and the covering pipes are parts of the case. Removable receptacle for the Fe-waste is a part of the product – it does not require any additional cleaning preparation

- Most user-friendly manual cleaning system = by pulling out of a separate component, operator working time loss reduction, high working safety level!

- High engineering workmanship level – the best materials are used, there is a high engineering workmanship precision, resistance, durability, assembling readiness

- Magnetic cores are permanently covered with covering sacs and there thus is no risk of their polluting or damaging during the cleaning process

According to required magnetic separation level, technology protection or product protection, magnetic core may be equipped with various magnetic circuit assemblies, namely on two standardized levels. There is preferred either the magnetic induction value, or the tear-off force value. According to these criteria, core composition on the levels I. to II. is selected.

Separator safety and quality information

We care about the high quality of our magnetic separators

MSVR STANDARD – UP general technical specification

Magnetic equipment

- Very strong NdFeB magnets located in the covering pipes

- Inter-circular magnet outer Ø= 29 mm, pipe outer Ø= 31-32 mm according to the magnetic output required

Magnetic material temperature resistance

- As a standard: up to 80 ˚C

- As an option: up to 150 ˚C

Magnetic output

- by a selection of the 2 levels, I – II according to the separation task and operational conditions

Grate system

- rotational, pulling-out magnetic cores, stationary – fixed covering pipes

Dropping labyrinth

- due to the rotating component, the maximum dropping labyrinth is ensured

Case and magnetic component material

- as a standard: stainless steel 1.4301 / AISI 304

- as an option: stainless steel 1.4404 / AISI 316L (for acidic pH environments)

Door sealing material

- as a standard: rubber sealing in a quality given by the separation task and operational conditions

- as an option: food industry sealing conforming to the food industry requirements

All materials are quality-certified according to EU norms.

Surface treatment

- outer case surfaces and grate frame: machine-blasted using a ceramics mixture

- grate pipe outer surface: machine-blasted or polished (as an option)

inner case surfaces are machine-blasted, for the food industry applications, corners and welds inside of the case are machined according to requirements of the food industry norms (as an option)

Connecting elements

- as a standard: flange according to an appropriate pipeline dimensions

- counter-flanges are parts of the product scope of supply

Linear guidance of the travel

- very precise linear guidance, dust-tight sliding surfaces

The material of the covering flexible sac (magnetic core covering sac during the cleaning operation)

- Kortexin

Engineering workmanship

- Quality and precise engineering workmanship is guaranteed

All engineering workmanship operations are carried out on machines belonging to the company production facility, using own MAGSY CZ engineering technologies.

Component welds

They are performed according to requirements of valid technological norms dealing with stainless steel material welding. Demanding outgoing weld quality control guarantees a high outgoing production quality.