Manual cleaning

What material do you separate

Flour

Ground paprika

Pâté

Sand

Gypsum

Sugar meal

Ceramic mass

Baby food

Lime

The above materials are only selected examples, consultation for your specific case is always important.

Contact us

Do you have a question or are you interested in a no-obligation quotation?

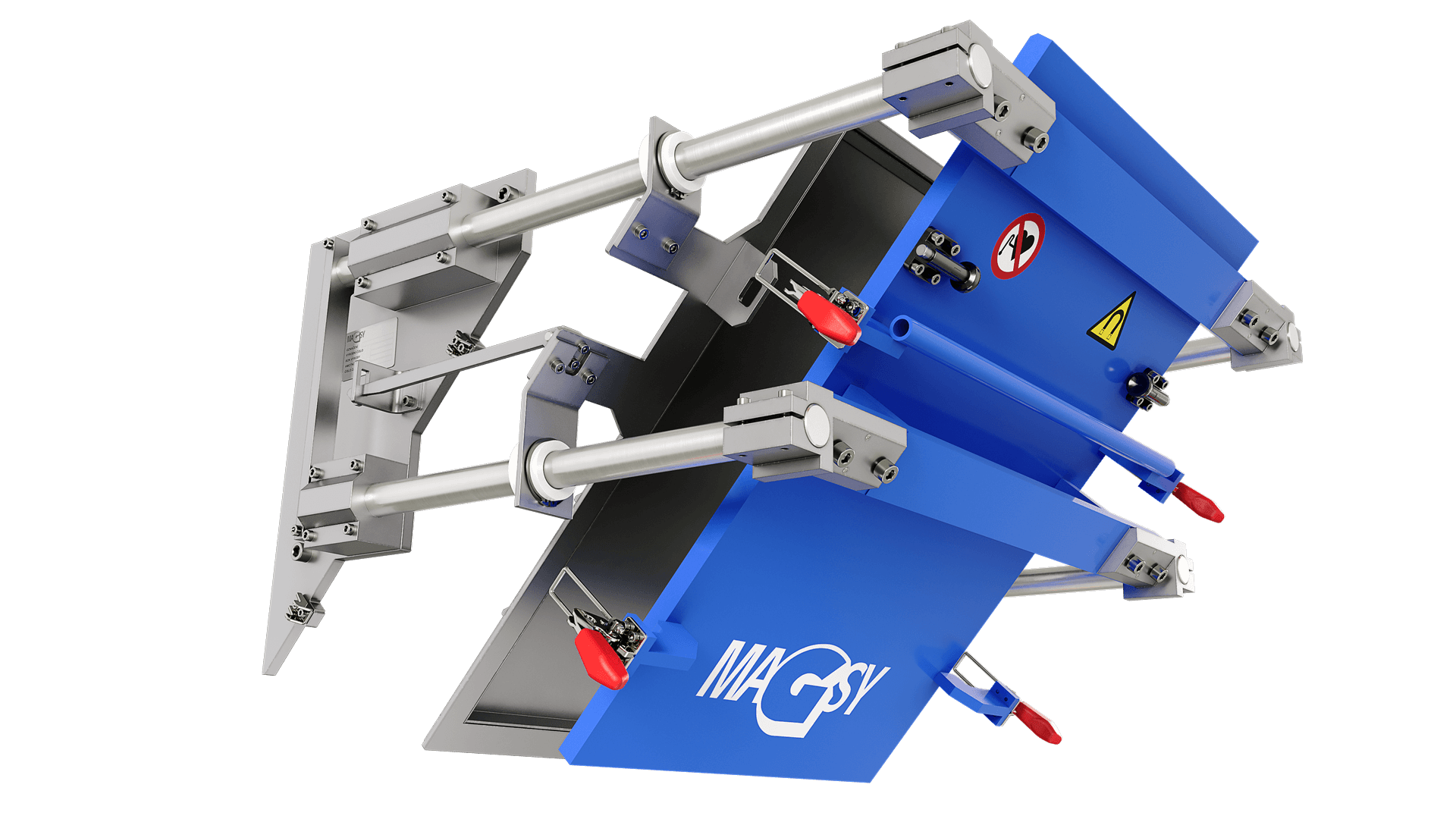

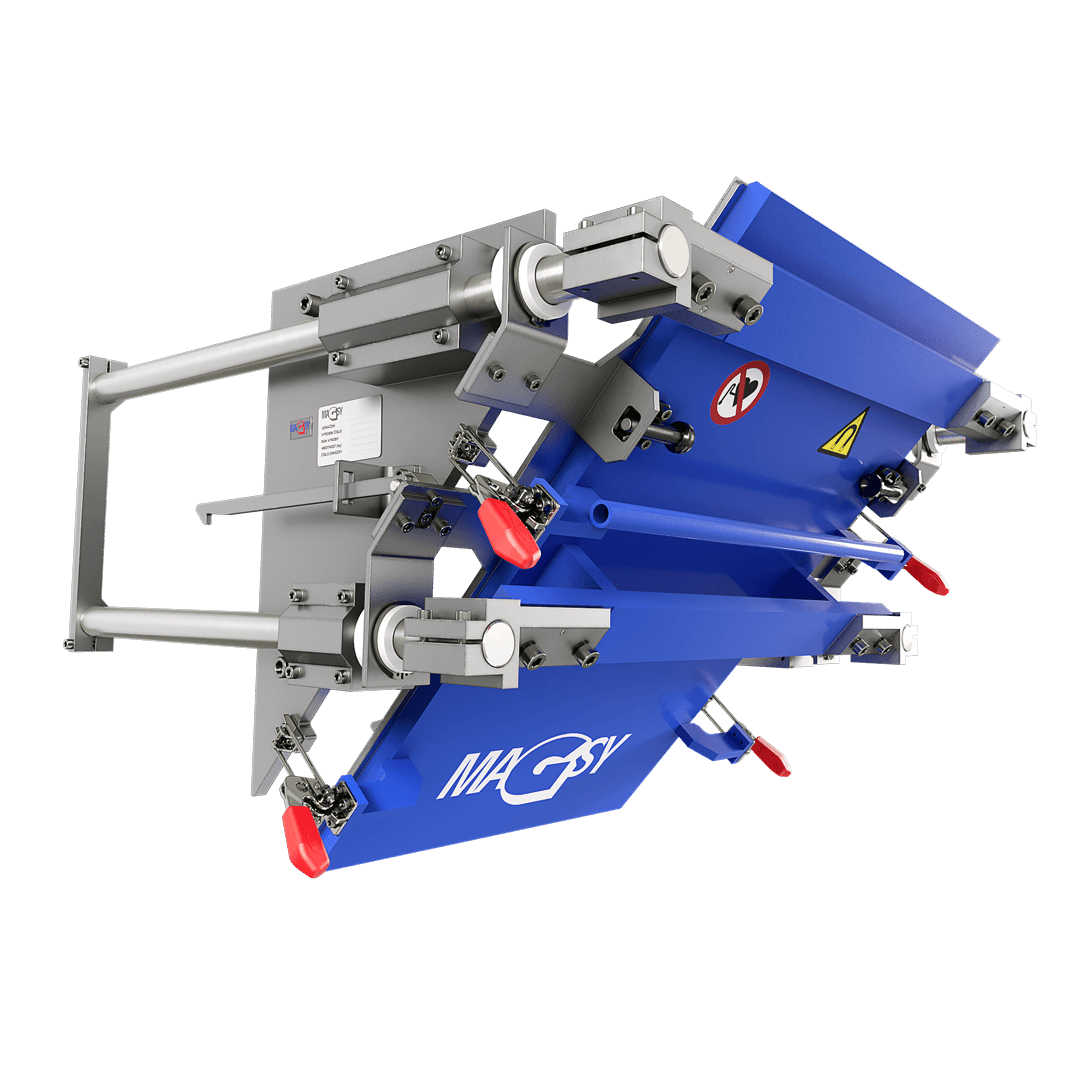

Magnetic door

What is the separator suitable for?

-

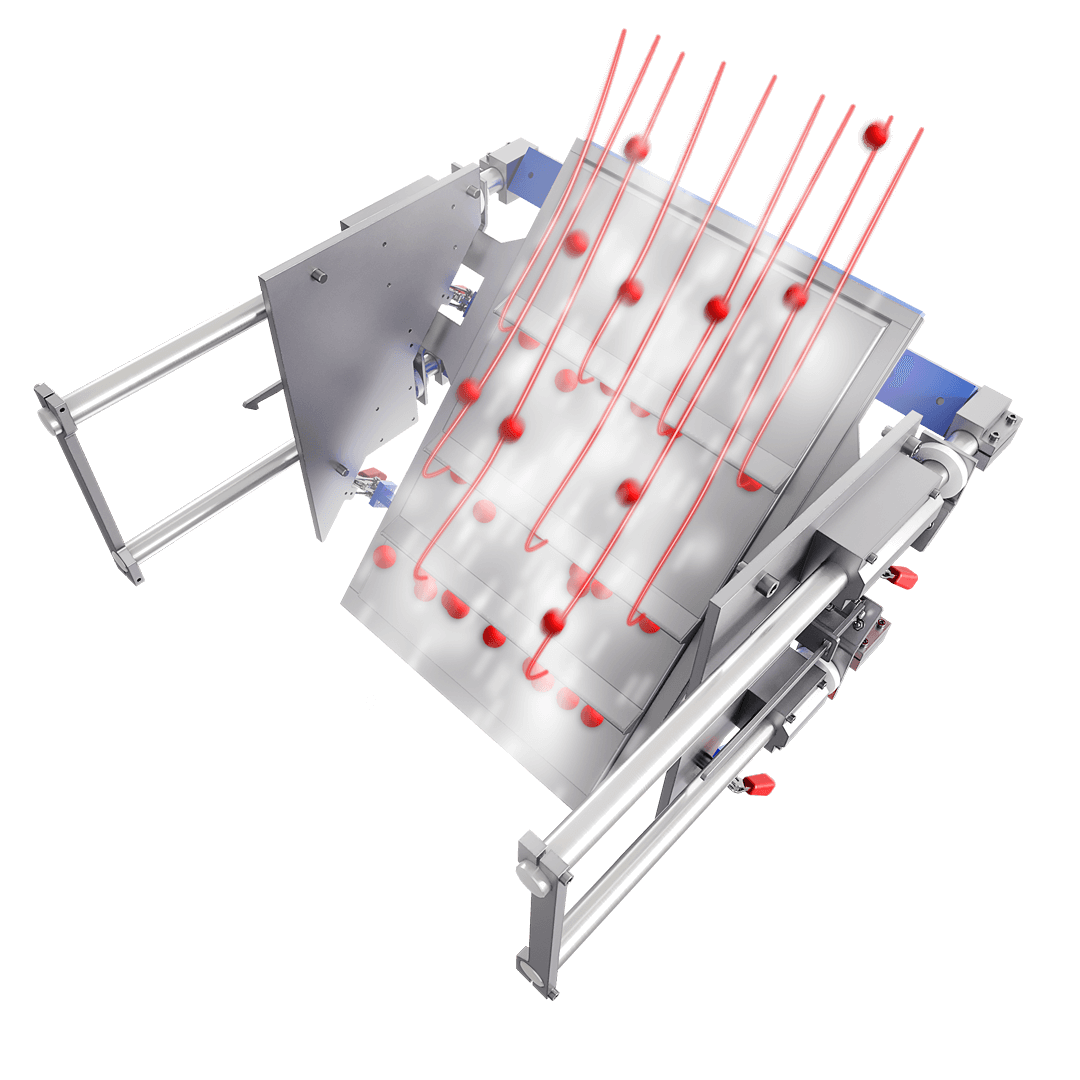

- Separation of metallic impurities from poorly permeable materials.

- Removal of larger particles, such as screws and nails, from abrasive materials.

- Installation in pipelines or behind conveyors during material processing.

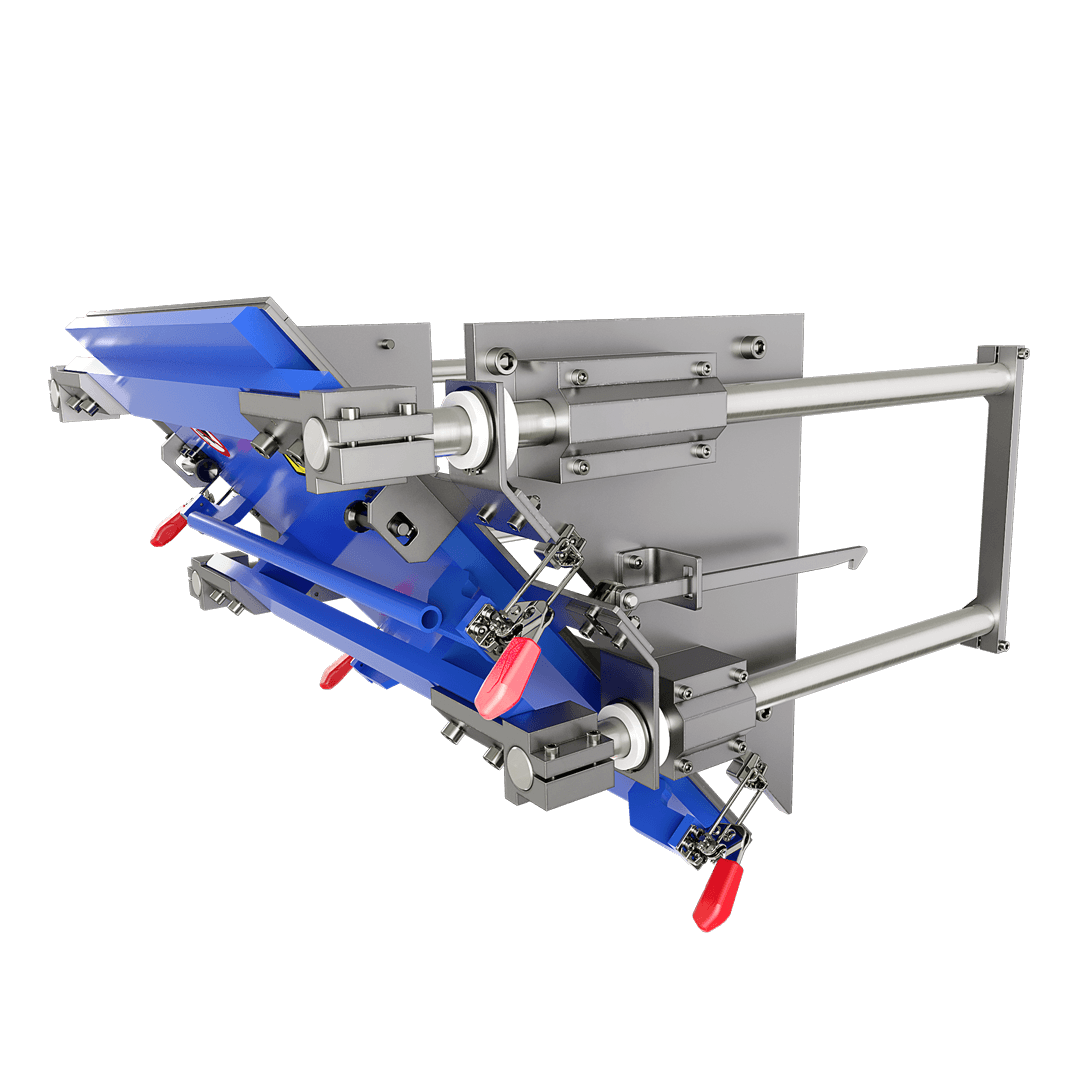

Design and cleaning principle of the separator

Important parts of the separator

Send us an e-mail

Aveți o întrebare sau sunteți interesat de o ofertă fără caracter obligatoriu?

Why Magsy

Own production hall

23 years on the market

Leading separator manufacturer in Europe

Service team 24 hours a day

Over 50,000+ separators produced

ISO 9001 certificates

How do we pack and ship magnetic separators?

How does the cooperation work?

Product Description

MD is manufactured in a way that it may be installed into pipelines with an inclination. It may also be installed behind the returning drum of the conveyor, in a way that separated material falls to the door where metal impurities remain caught.

MDV standardly manufactured models and sizes:- At present we do not have any compact product series – separators are always manufactured according to customer requirements that also applies to larger sizes (500×500 mm, 800×500 mm)