Automatic cleaning

What material do you separate

Vegetable oil

Gasoline

Diesel

Rinsing baths

Pudding

Syrup

Cooling emulsion

Cooling oil

Sugar juice

Jam

Yoghurt

Ketchup

Baby food

The above materials are only selected examples, consultation for your specific case is always important.

Contact us

Do you have a question or are you interested in a no-obligation quotation?

Magnetic separation vessel

What is the separator suitable for?

-

- Separation of metal impurities even from heavily contaminated liquids.

- Possibility to separate large quantities of metal particles.

- Easy installation and variability of magnetic systems.

- Automated solution without the need for an operator.

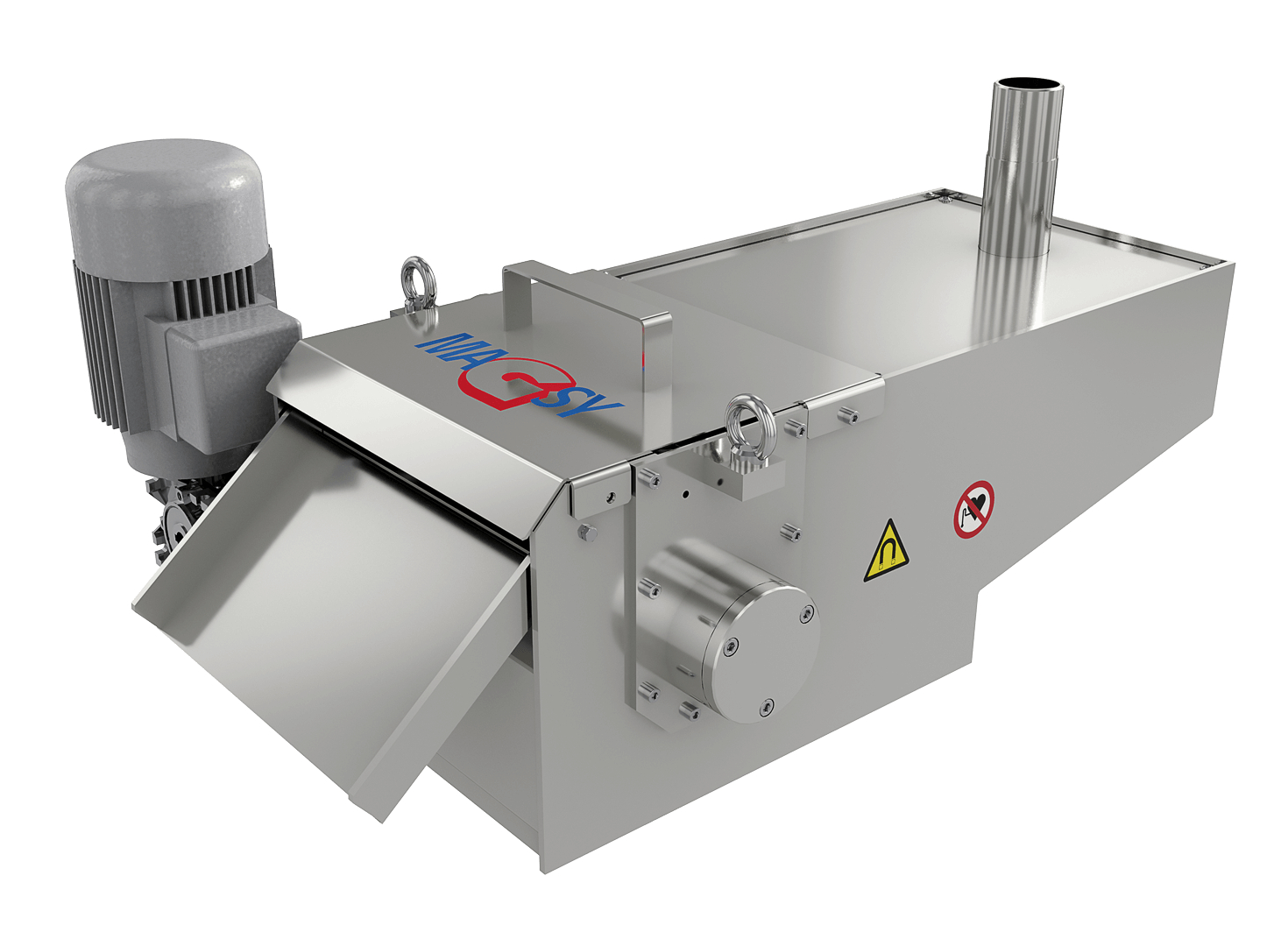

Design and cleaning principle of the separator

Important parts of the separator

Strong neodymium magnets

Inside the vessel are strong neodymium magnets that effectively capture ferromagnetic impurities from liquids and enable the separation of large quantities of metallic impurities.Stainless steel container

The durable stainless steel container ensures a long service life and is also suitable for food and pharmaceutical applications.Easy handling and cleaning

The vessel design allows for quick disassembly and easy cleaning, reducing downtime and facilitating maintenance.Send us an e-mail

Aveți o întrebare sau sunteți interesat de o ofertă fără caracter obligatoriu?

Model series

Why Magsy

Own production hall

23 years on the market

Leading separator manufacturer in Europe

Service team 24 hours a day

Over 50,000+ separators produced

ISO 9001 certificates

How do we pack and ship magnetic separators?

How does the cooperation work?

Product Description

Separation vessel may significantly increase separated medium (water, oil, emulsion, …) lifetime, and also the quality of the following manufacturing processes (e.g. reduction of costs of machining tools grinding) may be increased significantly. Very often, magnetic separation vessel is recommended as a secondary separation element in automatic flow-type separators.

Industrial areas of MSN utilization ...