-

- Automatic cleaning

- Liquid mixtures

- Magnetic separation vessel MSN Classic

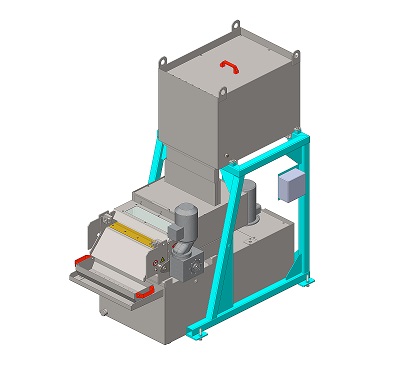

Magnetic separation vessel MSN Classic

This separation vessel is designed for a separation of metal magnetic impurities from the liquids. It is equipped with a magnetic cylinder catching metal magnetic impurities. Separated (cleaned) liquid FLOWS OUT SPONTANEOUSLY from the separation vessel. Separation vessel classic is designed for installations on places where the separated (cleaned) liquid does not have to be drawn back to the system but may be left to flow spontaneously (gravitationally) to e.g. collecting vessel with the liquid. Separation vessel classic is more often installed in a way it is located on a container with the liquid separated.

More detailed information

MSN-Classic standardly manufactured models and sizes:

We design the vessel size based on the liquid flow rate required.

Main benefits of MSN – Classic separator:

- Separation from even extremely polluted liquids

- Possibility to be used in situations when big quantities of metal impurities need to be separated

- Easy installation

- Possibility of magnetic cylinder equipment with both ferrite and neodymium magnets

- Automated separator type, without a need of human operation

- Easy solution from the separation from liquids

Separator safety and quality information

We care about the high quality of our magnetic separators

MSN – Classic separator design:

- This separation vessel consists of one (upper) container equipped with a magnetic cylinder

- Separated liquid is drawn into this container (ideally continuously, not in batches)

- Liquid pumping to the separation tank is provided by a customer (or, possibly, the liquid flows spontaneously, using gravitation)

- The upper tank is equipped with a well-done bulwark, in order to prevent the liquid overflow from the tank

- The liquid flows below the magnetic cylinder capable of magnetic impurity catching. Then the cleaned liquid FLOWS OUT SPONTANEOUSLY from the separation tank.

- Most often, the separation tank is installed in a way that it is put on the container with the separated liquid; cleaned liquid flows then spontaneously back to this tank

- Ferrite or very strong NdFeB magnets

- As a standard: up to 80 ˚C

- Ferrite magnets: 1500 – 2000 G

- Neodymium NdFeB magnets: 5000 G

- Separator cleaning is carried out automatically, by wiping impurities off the magnetic cylinder

- Impurities caught fall off to the collecting vessel

- As a standard: stainless steel 1.4301 / AISI 304.

- As an option: stainless steel 1.4404 / AISI 316L (for acidic pH values)

Magnetic equipment

- Ferrite or very strong NdFeB magnets

Magnetic material temperature resistance

- As a standard: up to 80 ˚C

Magnetic output

- ferrite magnets: 1500 – 2000 G

- neodymium NdFeB magnets: 4000 – 5000 G

Separator cleaning

- Separator cleaning is carried out automatically, by wiping impurities off the magnetic cylinder

- Impurities caught fall off to the collecting vessel

Material

- As a standard: stainless steel 1.4301 / AISI 304.

- As an option: stainless steel 1.4404 / AISI 316L (for acidic pH values / environments)

Engineering workmanship

All engineering workmanship operations are performed using own production equipment and own MAGSY CZ engineering technology.

Component welds

They are performed according to requirements of technological standards valid for stainless material welding. Demanding outgoing weld inspection guaranties the high final product quality.

Ask us – we will advise you!

Made-to-measure production is our strength.