-

- Liquid mixtures

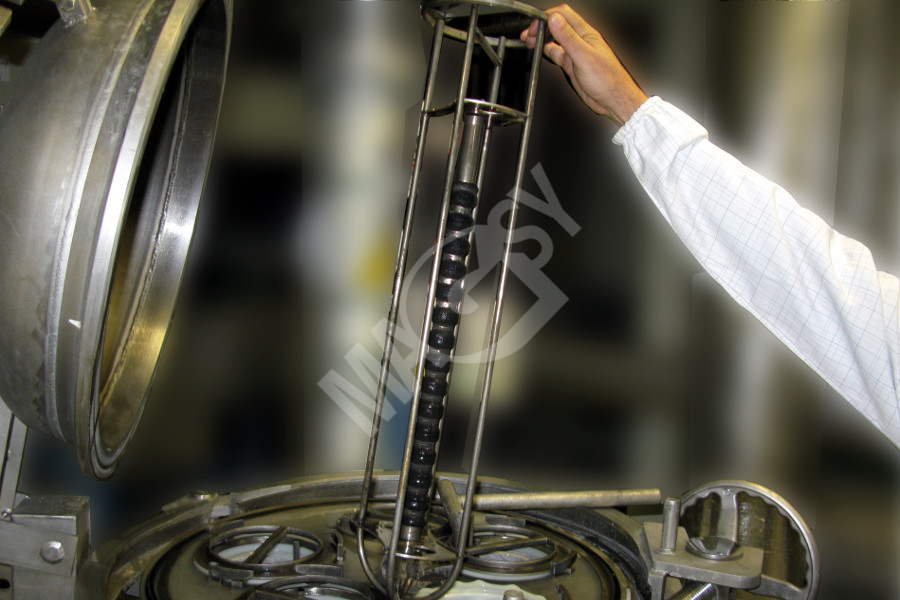

- Manual cleaning

- Magnets to be used in textile filters / Filter bag magnet (MTF)

Magnets to be used in textile filters / Filter bag magnet (MTF)

Directly for a sake of catching, magnetic separation of even the finest metal magnetic impurities in liquids, there were developed these magnetic rods, installed in a special holder called generally „Magnetic separators to be used in textile filters“. In case of their installation, you increase your chance to catch these impurities to the maximum level, saving thus costs related to very frequent textile material filter replacement operations. Our internal study confirmed that almost 45% of impurities that need to be caught, are of a magnetic nature, and their size is often such small (below 1.5 µm – with a “slimy mud” characteristics) that the filters characterized by limited filtration eye dimensions are without a chance to catch them.

More detailed information

Utilization area

- Chemical industry

- Food industry

- Pharmaceutical industry

- Mechanical engineering

- Ceramics production

- …and many other industrial areas where metal magnetic impurities need to be caught from liquids, or similar liquid-like matters transported using filtration assemblies

Magnetic solution

In some separation applications, deeper magnetic circuits must be chosen in a way that metal impurities are partly attracted even from a longer distance.

More about the magnetic induction measurement and our magnetic rod parameters

However, in any case, as close as possible metal impurity contact with the magnetic rod in question must be provided. In case of textile filters, there is usually hard to find this out so the contact with magnetic rods is compensated by a longer time for which the liquid remains in the candle filter. Amongst others, this impacts to an increase of technological times. Because of that, our company also offers a possibility of the magnetic separation improvement, by an installation of two magnetic rods into a specially modified magnetic rod holder. Due to that, the time to be spent in the filtration unit does not have to be extended so the probability of ferromagnetic impurity catching becomes increased just due to the quantitative stiffening of the magnetic rods in the holder. For a sake of completeness, you may download a graph where it is displayed how the magnetic induction and tear-off force values decrease as a function on a distance from the magnetic rod. This confirms the fact that more rods installed increase the probability of ferromagnetic impurity catching.

Technical solution

Magnetic rods are installed in specially designed holders developed directly for most of the filter dimensions, capable of containing one or two magnetic rods. In a comfortable and ergonomic way, the holder fits to the groove located in the candle-like filter, so during its installation, the maximum tightness of the entire system is guaranteed. The number of rods to be installed is given by the production technology and customer requirements regarding the outgoing magnetic separation – see the section above.

https://youtu.be/dW1cH6QXh9o

Magnet for textile filters, with one rod

Magnet for textile filters, with a single rod (MTF – 1) – it consists of one magnetic rod + stainless-steel carrier for that rod

Magnet for textile filters, with two rods

Magnet for textile filters, with two rods (MTF – 2) – it consists of two magnetic rods + stainless steel carrier for the two rods

Magnetic rods

Final surface treatment uses polishing, with the final surface guaranteed for the polish level of Ra = 0.02µm – in order to achieve as smooth as possible surface by the reason of prevention of creating micro-fissures where impurities may accumulate, making thus unwanted „crusting“ effect. This 100 % smooth surface also guaranties very comfortable and trouble-less cleaning.

In the lower magnetic rod part, there is situated a pin-like projection the location of which is comfortable and precise – magnetic rod is installed into its holder.

In the upper part, an embedment is designed providing perfect securing of the magnetic rod during its installation into the auxiliary holder.

A specially designed, so called open magnetic circuit, with a shorter or longer arch between the pole extensions, guarantees a maximum magnetic – tear-off force corresponding to your needs.

The material is a standard stainless steel 1.4301 / AISI 304. By request, if needed in environments characterized by aggressive pH values, we can supply the product as made of the 1.4404 / AISI 316 material. All materials are in the quality corresponding to respective EU norms and possessing respective certifications.

As a standard, magnetic rod temperature resistance is up to 80 ˚C. By your request, we can prepare your magnetic rod also for using at higher temperatures, i.e. up to 200 ˚C (in case of even higher temperatures, please take into account decreasing of our standard magnetic parameters by ca 10 – 20 %, as depending on the thermal resistance chosen).

Magnetic rod holder

In the upper part of the magnetic rod holder, small telescopic piston is situated. The item provides a fixed magnetic rod securing in the holder and, also, its very comfortable removal upon cleaning.

Magnetic rod cleaning

After the magnetic rod has been removed (in case you afford the arrangement including two magnetic rods, please remove the rod in question from the holder in its axis direction. In respect to the fact that the magnetic circuit is ended to a sufficient extent before the rod end on both of the magnetic rod sides, metal impurities fall out very easily. However, it is very important to carry this process out using a personal protective equipment, in order to prevent hand injuries by sharp metal impurities that can also be collected on the rods.

Ask us – we will advise you!

Made-to-measure production is our strength.