Manual cleaning

What material do you separate

Flour

Sugar crystal

Ground paprika

Poppy seeds

Sand

Plastic granulate

Beet pulp

Sunflower seeds

Shot

Spices

The above materials are only selected examples, consultation for your specific case is always important.

Contact us

Do you have a question or are you interested in a no-obligation quotation?

Plate-type magnetic separator

What is the separator suitable for?

- For dry mixes with poorer spreading properties.

- Suitable for separation of abrasive materials.

- Also separates larger ferromagnetic materials (screws, nails,...).

- For circular and square pipes (we can also produce special sizes to order).

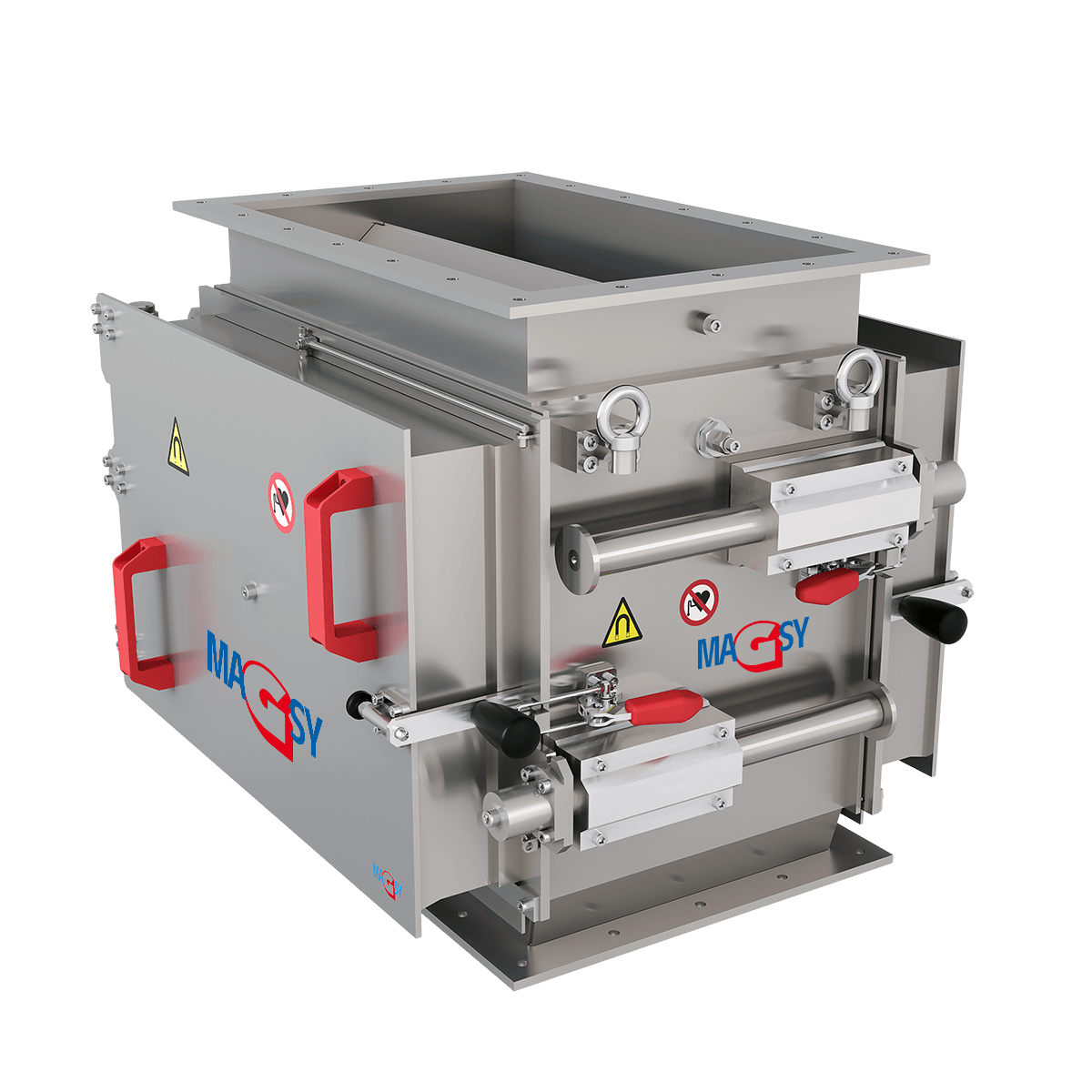

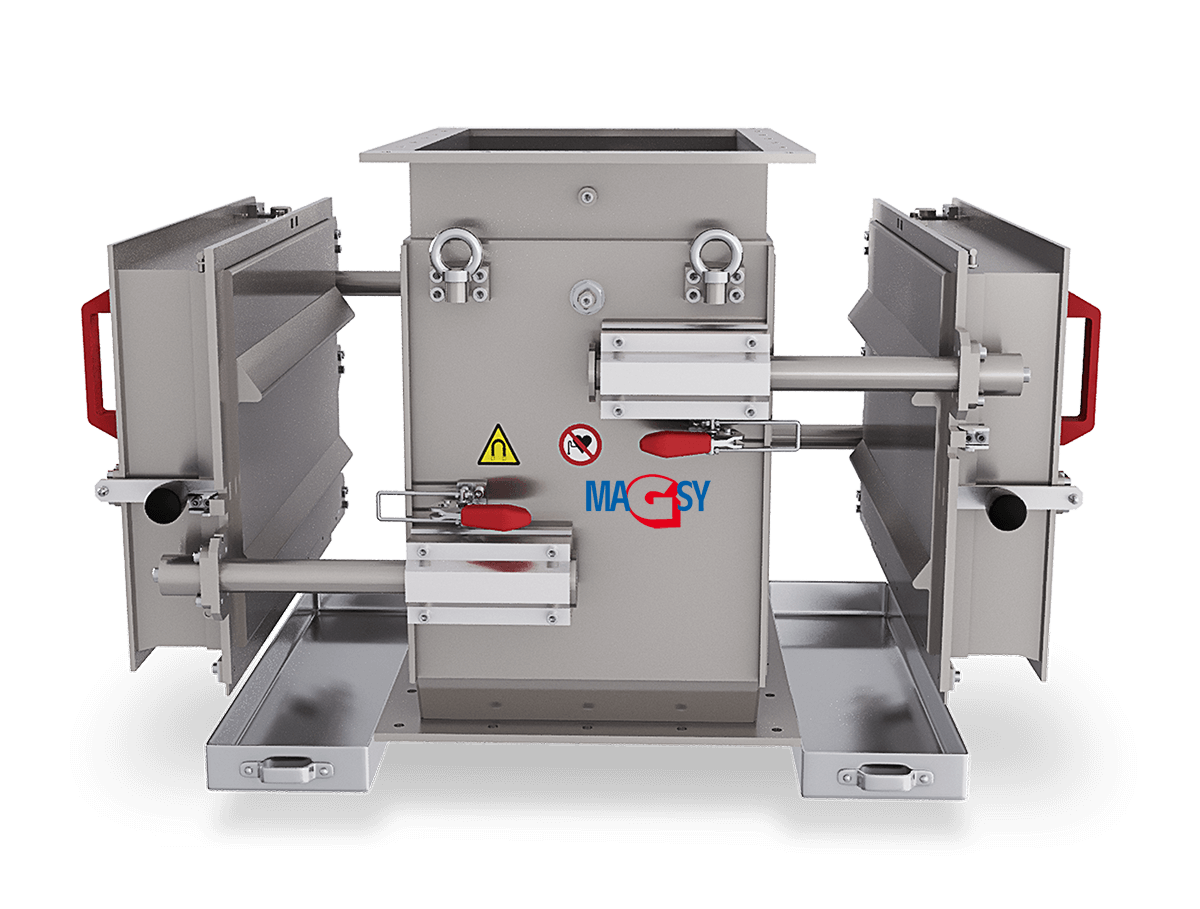

Design and cleaning principle of the separator

Important parts of the separator

IN/OUT

We can produce the required dimensions according to the customer's wishes. The model shown has an inlet and outlet of 500 x 300 mm with a flanged connection, which is standard on most of these products.TWO CANOPY SYSTEM

Two canopies serve as auxiliary technological elements, under which the magnetic force is the greatest. Metallic impurities are collected here and protected against being knocked down by falling material.

MAGNETIC PARTS CAPTURE SYSTEM

This model shown is one of the most technologically advanced designs and is made with two magnetic poles. One pole is deeper, extends more into the material and preemptively pulls out the metallic ferromagnetic impurity, while the other pole is shallower and its job is to firmly capture and hold the metallic impurity.MYSTERY BOWLS

Perfect capture of magnetic contaminants in the catch basins is a matter of course. The bowls are always included with the magnetic separator.

Send us an e-mail

Aveți o întrebare sau sunteți interesat de o ofertă fără caracter obligatoriu?

Model series

Why Magsy

Own production hall

23 years on the market

Leading separator manufacturer in Europe

Service team 24 hours a day

Over 50,000+ separators produced

ISO 9001 certificates

How do we pack and ship magnetic separators?

How does the cooperation work?

Product Description

Size models and the separator design

MSP-UP is manufactured either for a connecting to round, or square pipelines.

MSP-Classic standardly manufactured models and sizes:- For round pipelines with the diameters: 100; 150; 200; 250; 300 mm

- For square pipelines with the dimensions: 100×100; 150×150; 200×200; 250×250; 300×300 mm

MSP – UP separator main benefits ...